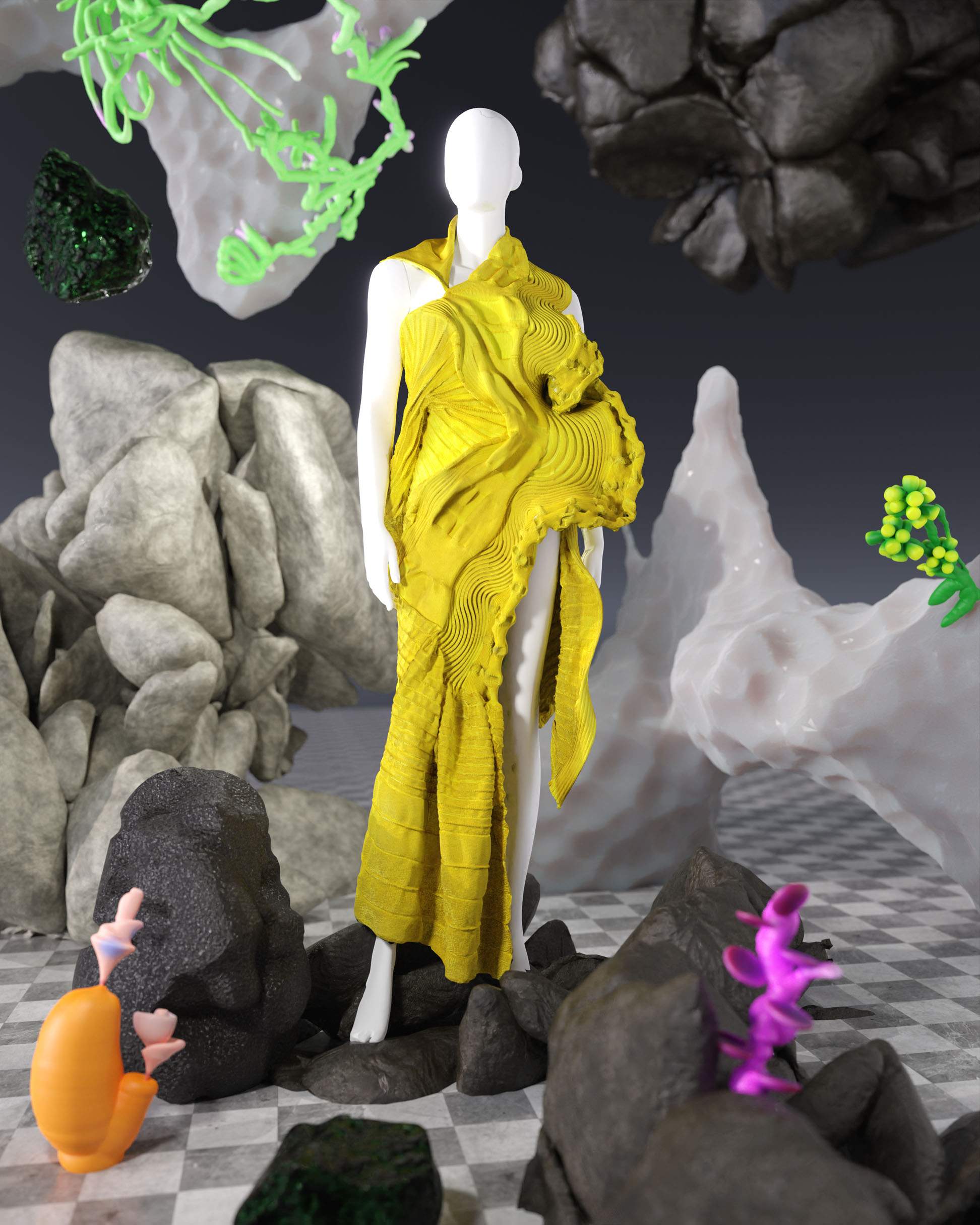

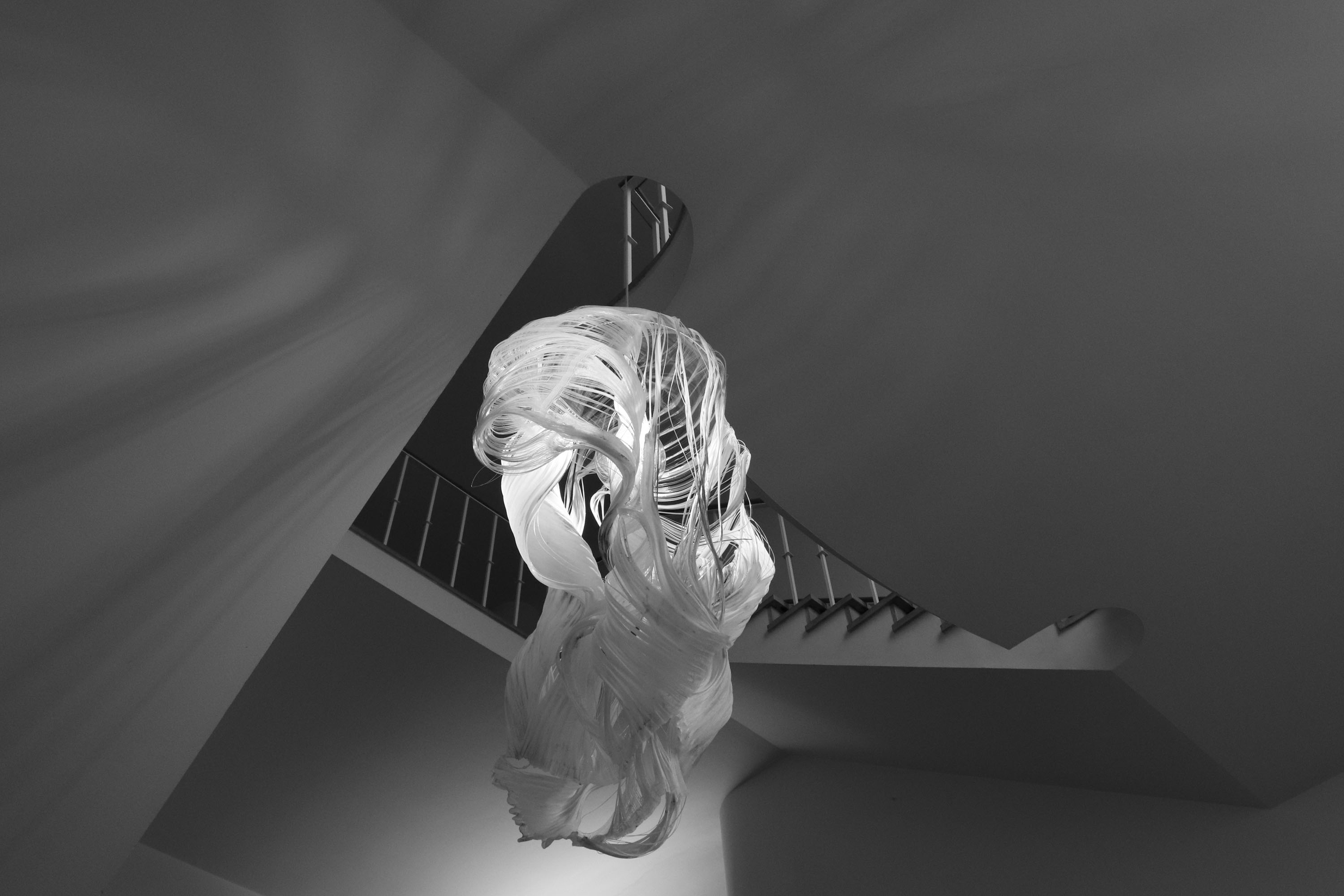

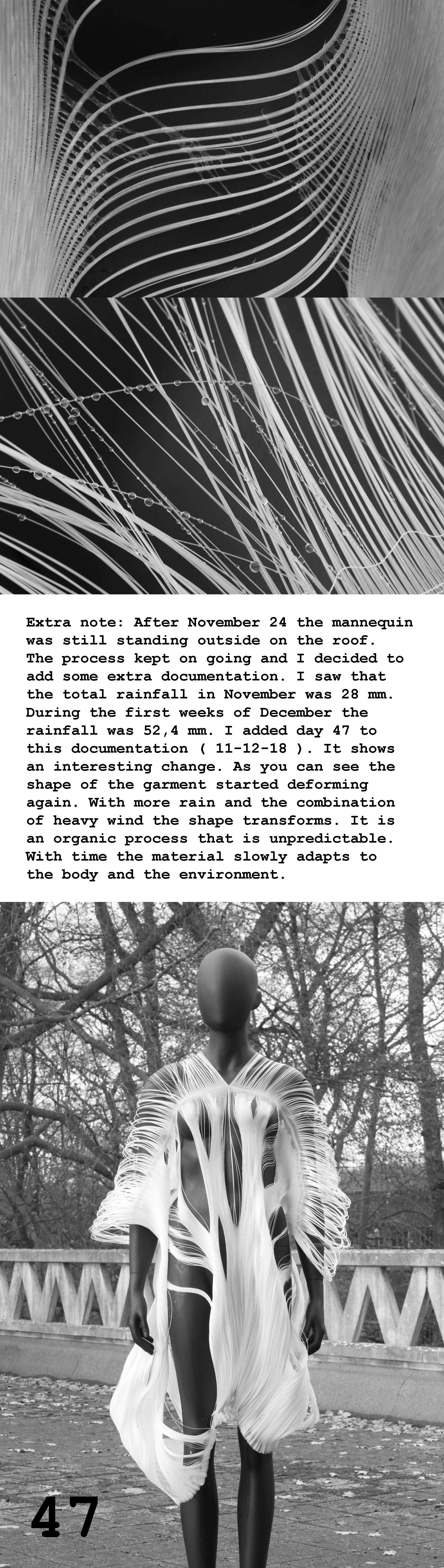

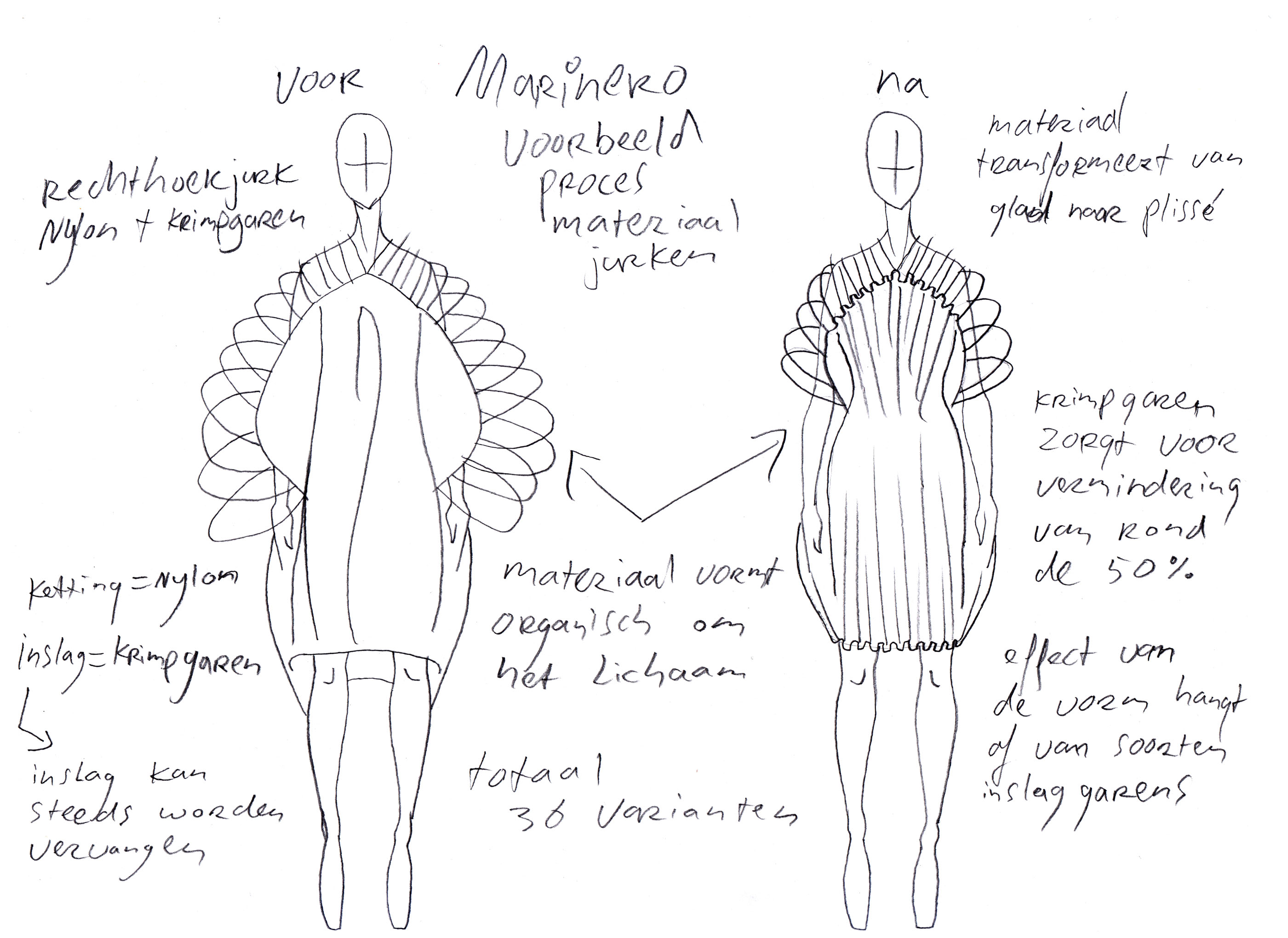

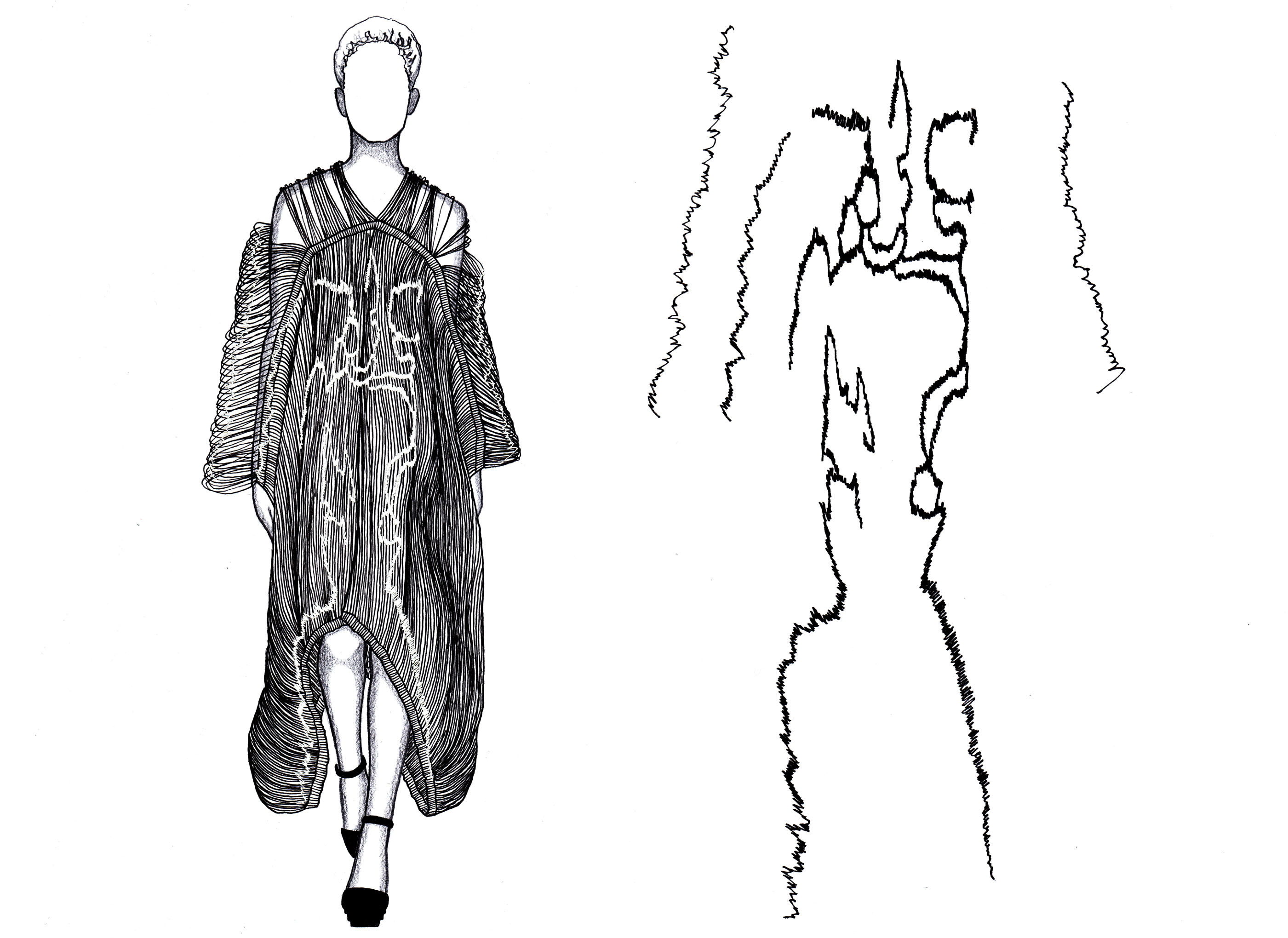

Fashion manufactured by rain. Project Marinero is created with the idea of using the environment as

the main design element, within the shaping process of materials. The

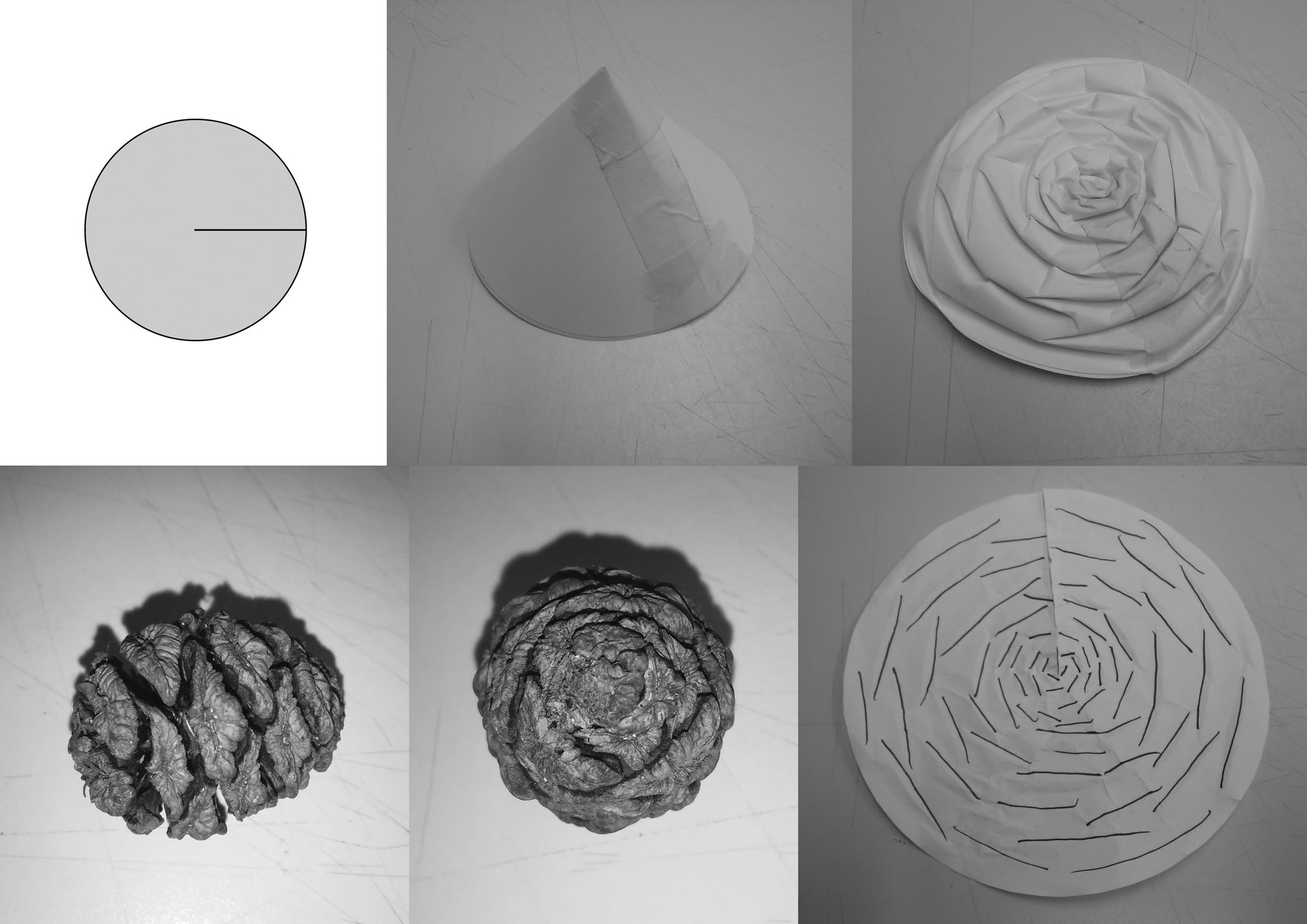

concept of the textile design comes from biomimicry, 2D elemental forms

that unravel into complex 3D shapes. I am inspired by the natural slow

process of growing plants and flowers. The elemental lines of leaves are

abstractly incorporated within the textile blueprints. All produced

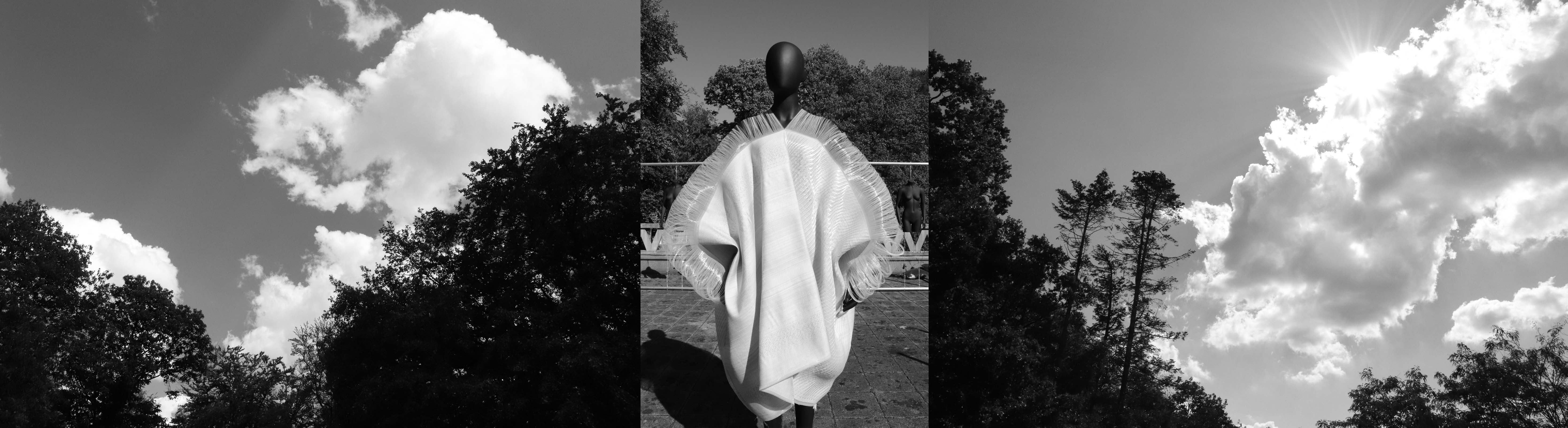

adaptive materials have been brought back to the nature, where

meteorological conditions slowly deformed the Marinero garments from 2D

to 3D.

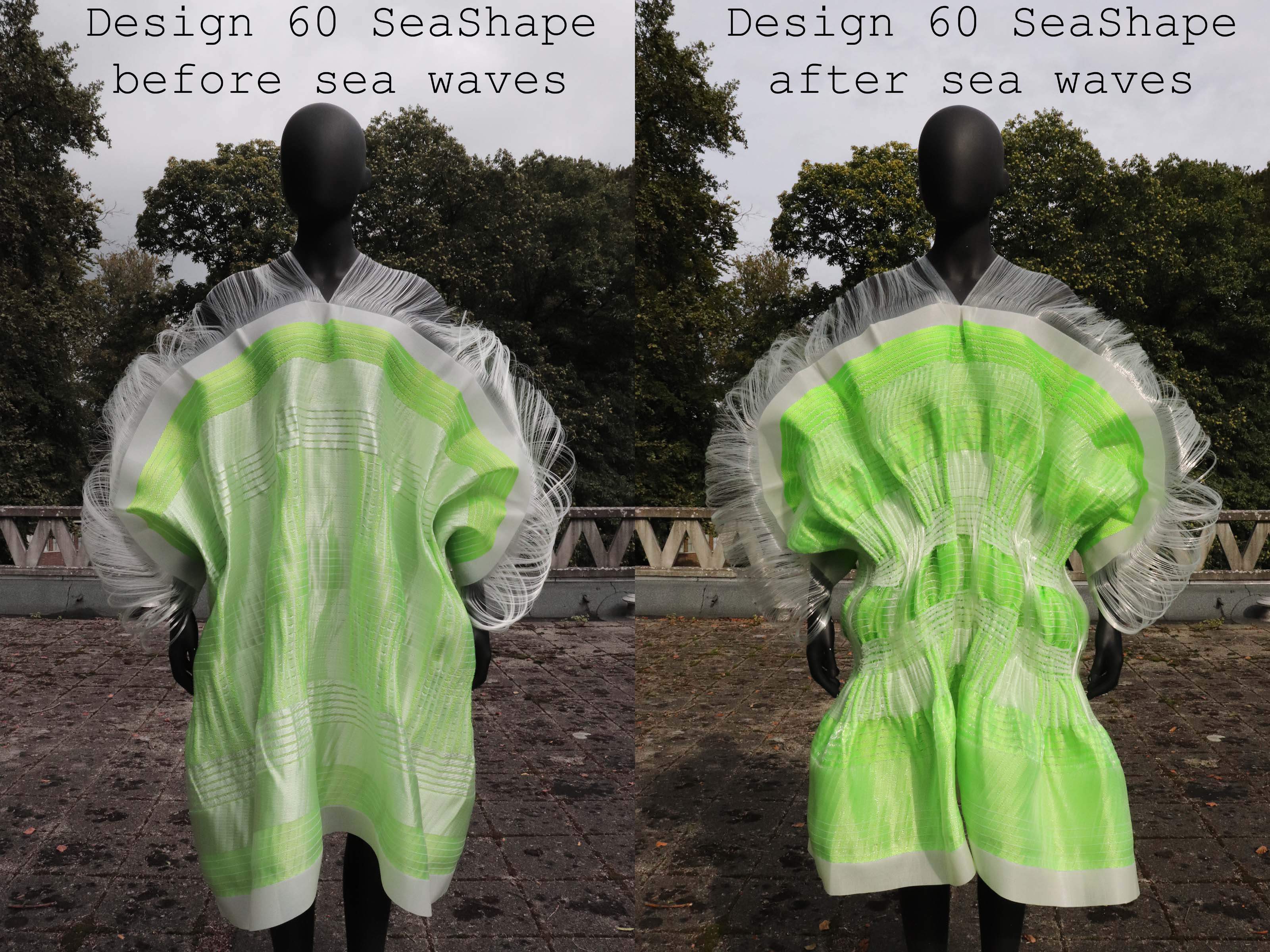

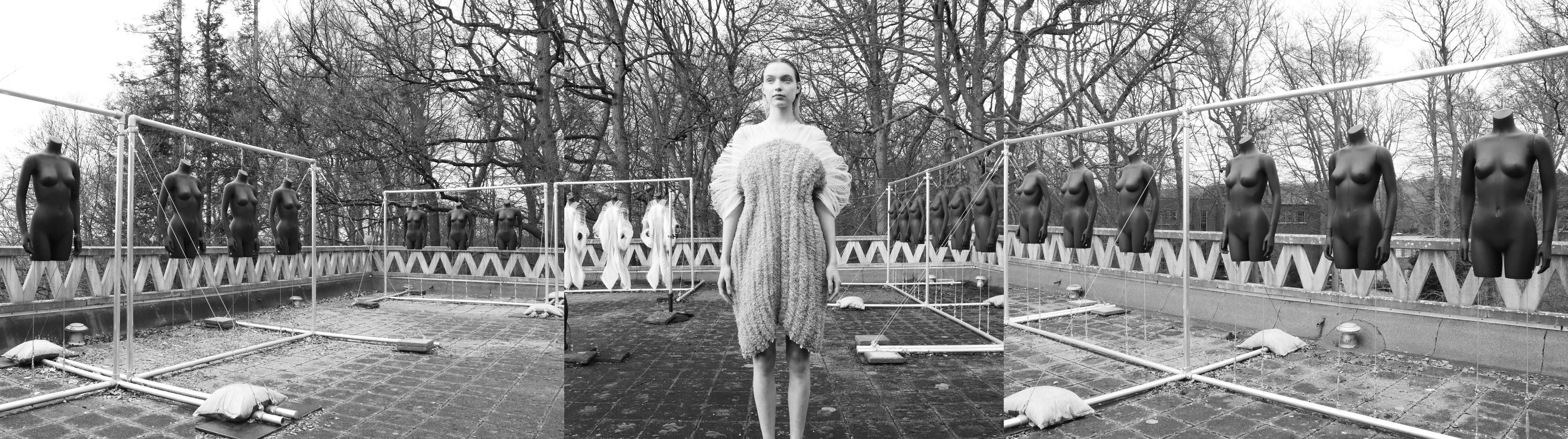

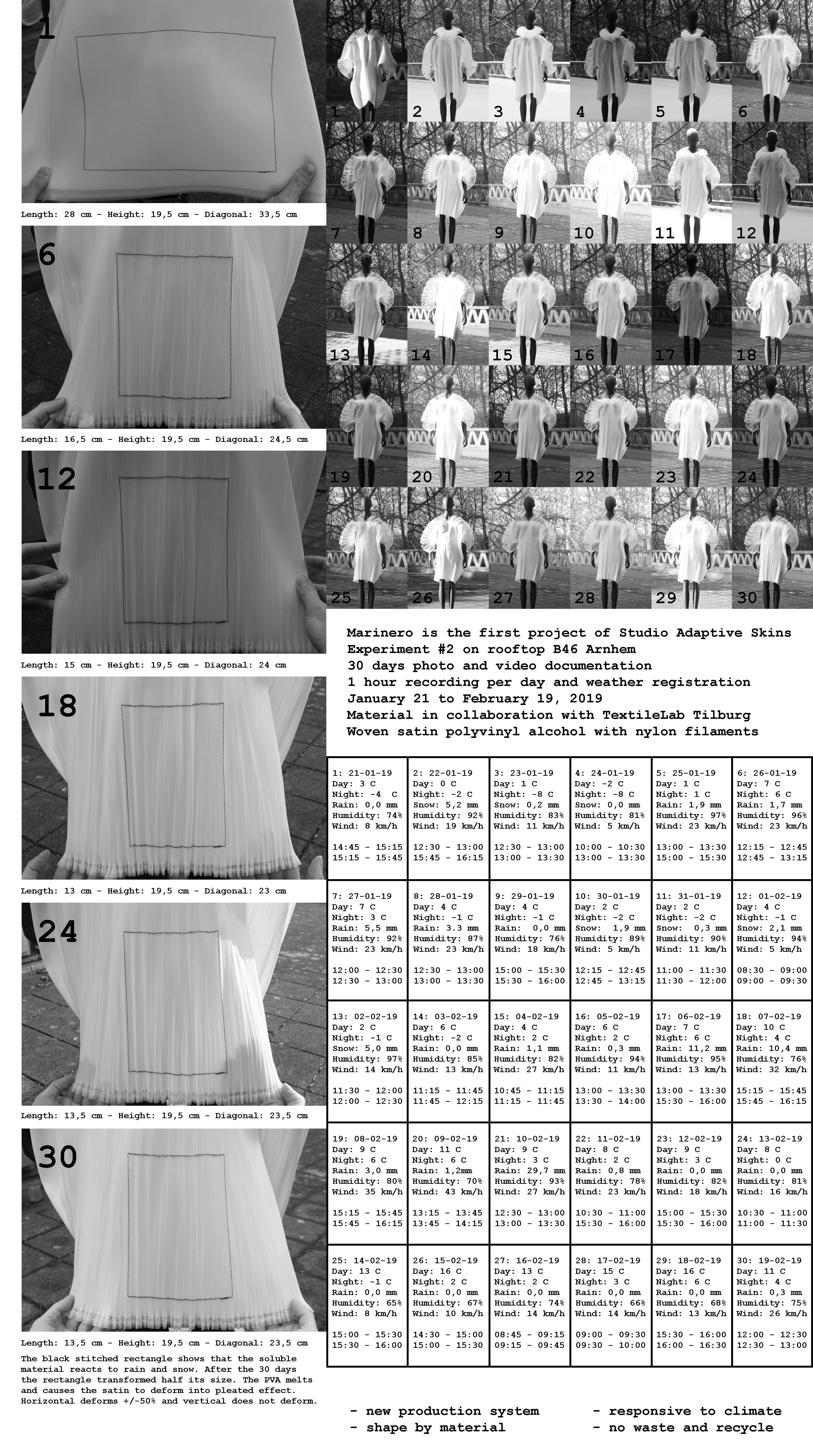

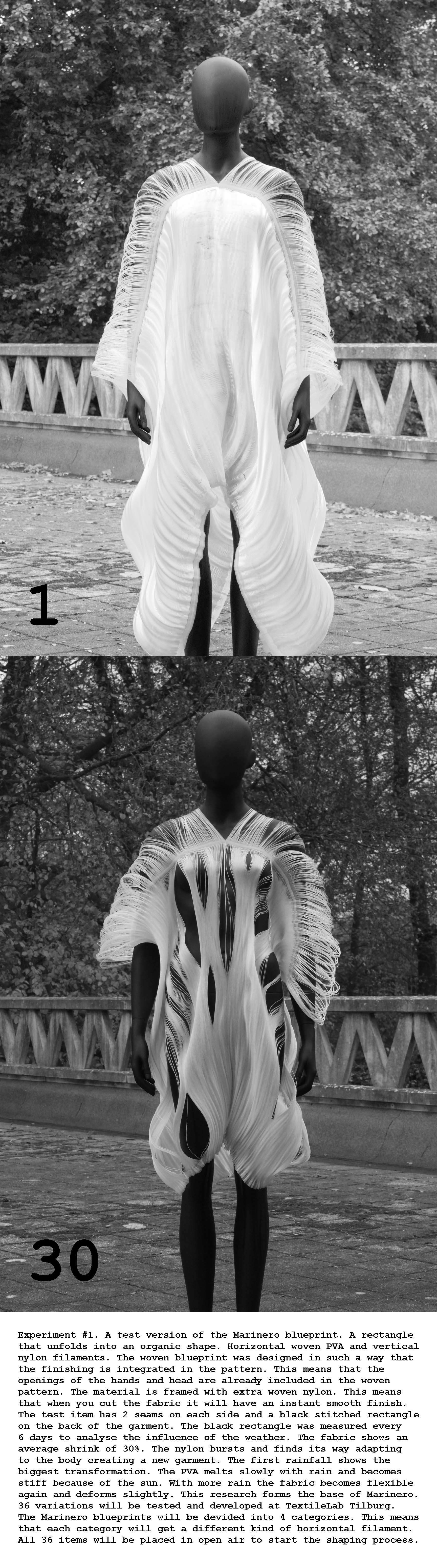

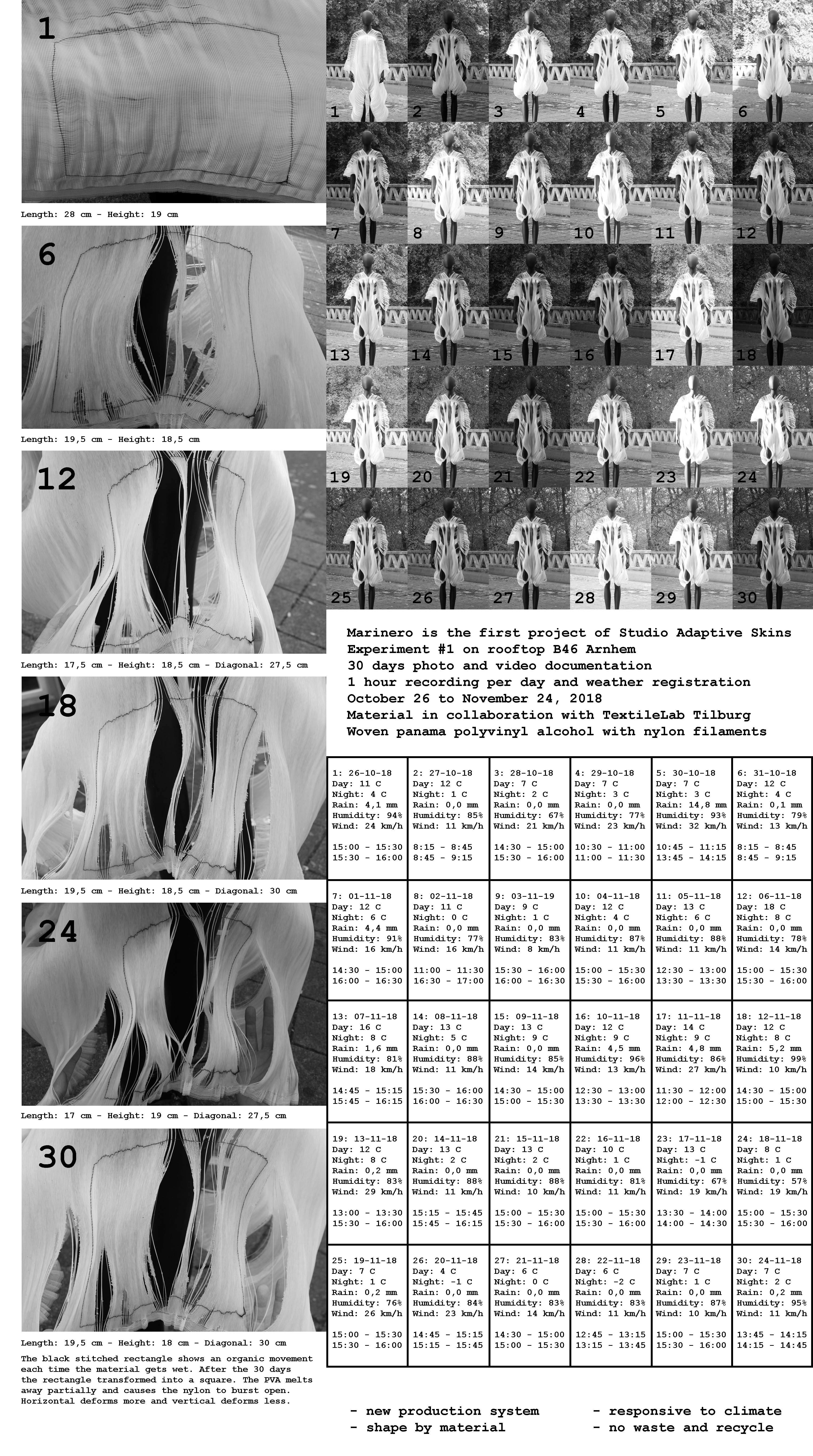

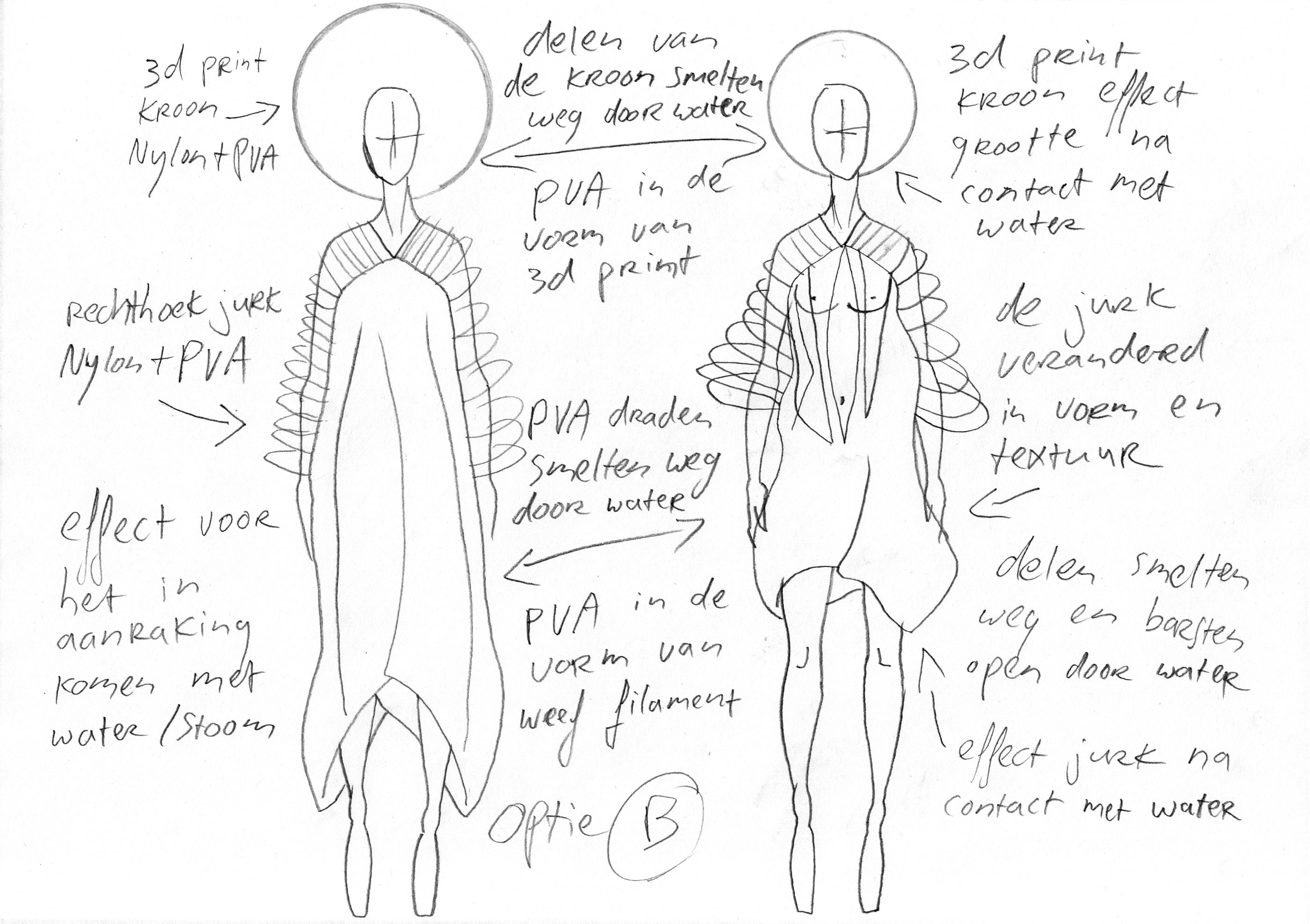

In order to emphasize the deformation of the textile it was needed to create conceptual yarns. The Adaptive Archi-Filament was developed in collaboration with Horizon 2020 co-creation tech platform Re-FREAM. I collaborated with Aitex Textile Institute Valencia, Johannes Kepler University Linz, Empa federal material laboratories St. Gallen and Wageningen University Research. The idea of the sustainable produced filament is to block deforming mechanisms inside a firm bio-plastic coating. These soluble layers melt away with rain and start to deform within woven and knitted structures.

The materials are developed in collaboration with TextileLab Tilburg. 66 Marinero designs were produced for the design follows material experiment. The outdoor installations are designed in collaboration with artist Bart Nijboer. This experiment lasted over 6 months and the entire process is published on the main page of studioadaptiveskins.com. Design 33 is the best result in terms of most dramatic 30 days rain experiment transformation. Design 51 shows the best balance of all the developed adaptive yarn prototypes versus tailored effect.

- Jef Montes {-} ”Adaptive yarns and bioplastic raindrop filaments. The goal of project Marinero is to

go

from 2D to 3D, using smart materials and to reach shape within the

architecture of a fabric. The molding process of the garment

is placed into a literal natural context.

This is an alternative production method that offers sustainable

solutions. The weather installation communicates in a poetic way to

bring more awareness about slow fashion and how precious the making

process of a fashion item actually is. We work with zero waste during

the tailoring process,

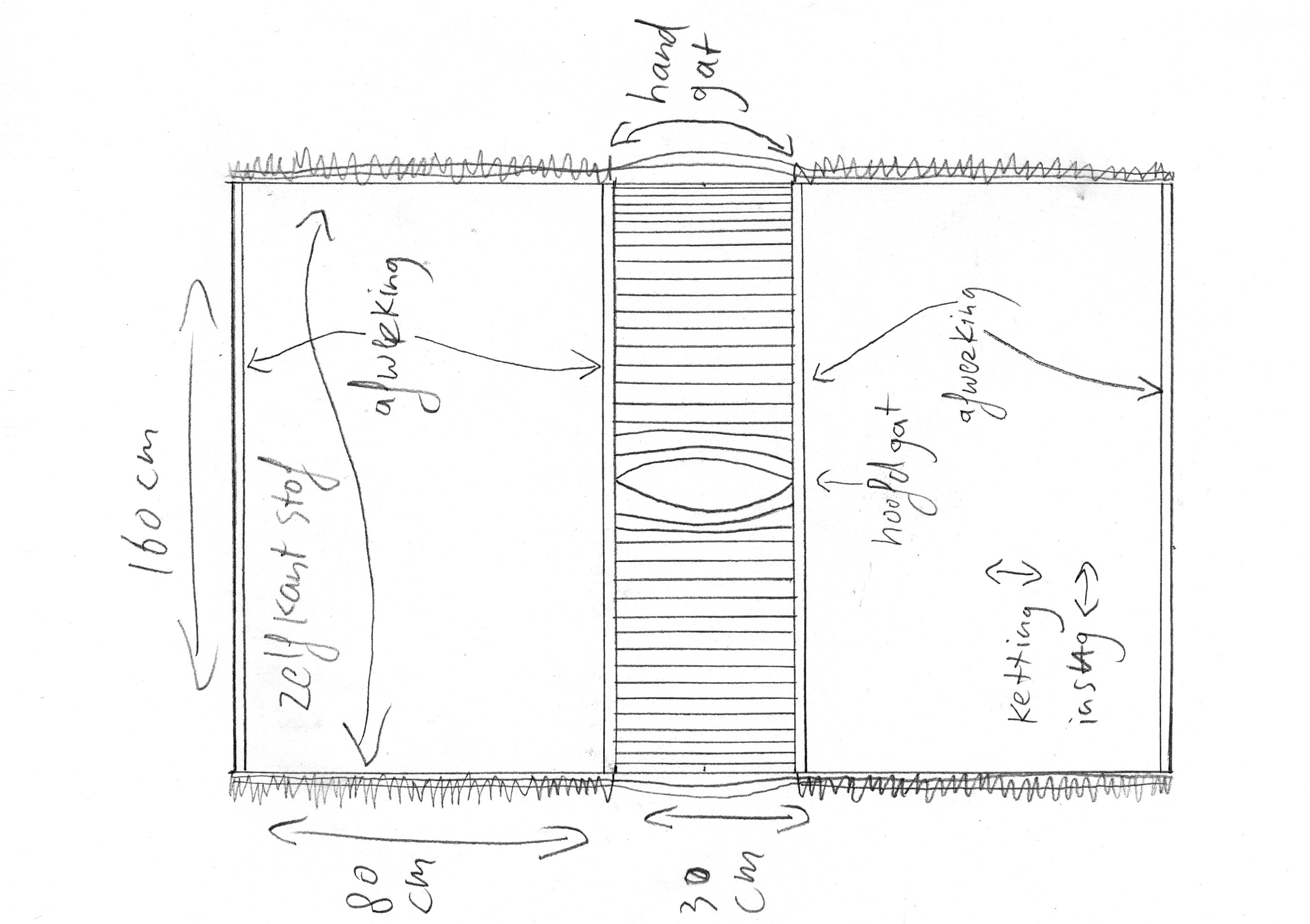

the Archi-Filaments do most of the shaping development. Within the

spectrum of weaving we work with square patterns, but with knitting we

can produce organic shapes without creating any waste. It's all about

design follows material and the benefit of the experiment, offering

unexpected beautiful shapes. My vision is that adaptive yarns will play

an

important role in the future, in order to reshape the architecture of a

garment.''

In 2019 Studio Adaptive Skins joined the Re-FREAM network. An international horizon 2020 project that aims to rethink the production process of fashion. The goal is to create a new fashion aesthetic, that is shaped within the natural frames of the technology. ''tailored by weather'' is the main concept of the collection. The idea was to create adaptive yarns that have unique mechanical components, allowing the material to create complex shapes within a textile. This means that 2D produced textiles deform into complex 3D shapes by the use of smart filaments, based on meteorological conditions. The main European co-creation hubs are: Aitex material technology institute in Alcoy/Valencia and Wood K Plus research institute, at the Johannes Kepler Institute in Linz. We have been working on recycling plastic from the sea (rPET, and also PLA bioplastics) to create the Adaptive Archi-Filament. The technology that we have been working on are: melt coating and dip coating production processes. To create the Archi-Filament we needed to adapt existing filament production machines. Our project partners from Empa, the federal material science laboratories in St.Gallen contributed in lab testing and sharing valuable yarn improvement information. This helped the filament production technicians to create the final high performing filament prototypes.