- Sepia ink: from food industry too (for the black)

-

Update 4: 29-07-2020

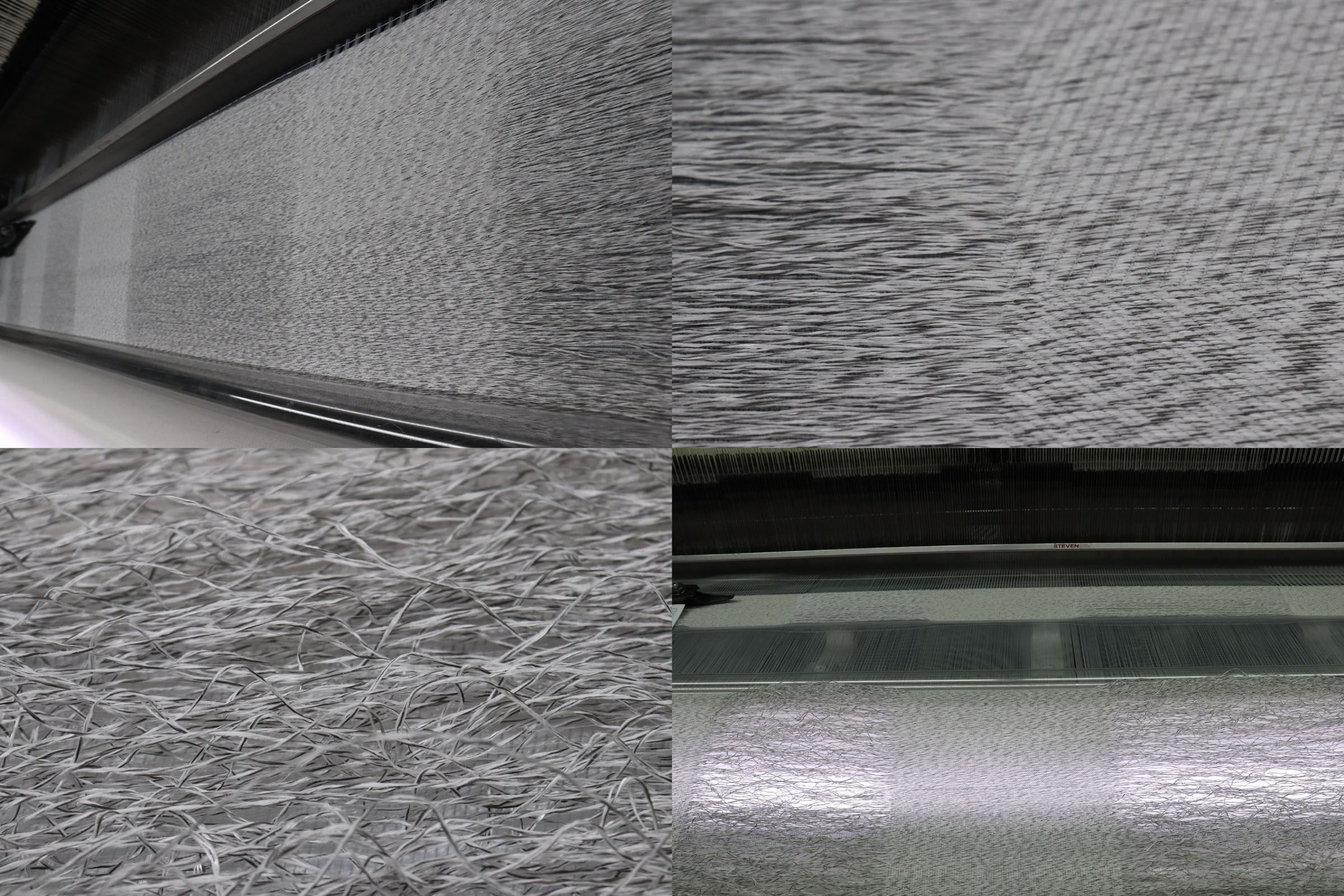

*Weaving Aitex category

During the production process we realized some obstacles that we needed to tackle asap, in order to continue the process. Luckily the team of TextileLab Tilburg was very helpful in finding solutions.

The first obstacle that we were surprised with were the dyed Seacell yarns. It turns out that Carolijn did not spool the yarns correctly onto the cones. During the production process we lost 4 entire cones ( 30 km yarn ). What happened was that the cones wrapped up into a spaghetti mess. I had to contact Carolijn in the middle of the night to ask for her help. She came during the morning to talk about the issues that we were having. There were only a few options left: I needed to choose the best looking quality yarn cones. The TextileLab technicians would assist Carolijn to rewind all those thousands meters of dyed yarns.

The second obstacle was that my product developer found out that there were not enough Aitex cones to produce all the fabrics. What the team from TextileLab did was offering me to duplicate the Aitex yarn. Meaning that we could add these new yarns to finish all the production. I thought this was an amazing solution. We looked for similar quality yarns and twisted these yarns together, almost looking exactly like the Aitex yarn. The only thing is that this new yarn produced at TextileLab did not have any coating or deforming effect. In the end it was the best solution, because these 2 yarns together give a beautiful quality to the final fabric design.

I learned that in the end we had some major challenges, but working together helped the entire project rising to another level. It seems to me that all these things needed to happen, in order to make the final design even better. It was a very interesting experience for me. We were able to do everything that I was hoping for. I am proud and happy with all the support and genuine help that came along the way. There is always room for improvement, but I am hoping to learn and grow step by step.

-

Update 3: 29-07-2020

*Weaving Seacell category

It was a very interesting moment for me to start working on the Marinero weaving production. I have been working on bringing 3D shapes into fabrics with TextileLab since 2014. So, it was very exciting for me to see all these new elements coming together. Within a time frame of a few weeks we needed to produce all the fabrics. I already knew that this was going to be a very intense moment for me. Luckily I had a great team around me that were supporting me throughout the production process.

The weaving process started with the Seacell category. My collaborative product developer Judith Peskens advised me to make a work plan for the weaving. We used our time to develop several test weaving fabrics. Each test fabric will be divided into several woven frames. This way we can choose what techniques we want to use for the fabric production. It is important that all changes made are chosen very carefully. Each change that you make can impact the entire process that you are working on. So it is very important that you stay clear and sharp at all times. Having an open mind and clear communication are the main key points that are needed throughout this whole process. Because wanting to change too much can make everybody confused, or even worse -> loosing yourself in all possible options and not seeing the bigger picture anymore.Having a clear prepared plan helped us go throughout this whole project step by step. For the first test we focused on single weaving layers, with several added Seacell yarns. We also added Aitex Archi-Filament, shrinking yarns and Rpet yarns. I really liked the combination of these yarns in terms of color. The techniques and styles that we used are: panama, twill and satin bindings in combination with variable gradient blueprints.

-

Update 2: 06-06-2020

The collaboration between Carolijn Slottje and Tjeerd Veenhoven has been very inspiring. For us as a team it was about the development process and joined research. Since the beginning Carolijn and Tjeerd have been very invested with this commission. It was difficult to schedule the exact time needed to prepare all this work. In the end they invested so much time and effort, dyeing all the Seacell yarns by the use of seaweed pigments. Most of the process has been done by hand. They even constructed a special machine to spool all the dyed yarns back onto the cones.

It has been a challenge to dye all the tied down yarns within the pigment baths. The yarns were laying on top of each other, so it was a bit difficult for the pigment to reach all the layers of the yarns. Carolijn and Tjeerd decided to dye 2 bundles in a bath of 55 liters seaweed pigment. This process of dyeing needed to repeat for over 4 times per bundle. They dyed around 60 KM Seacell yarns. After the drying process the final challenge was to spool all the dyed yarns back onto the cones.

The first bundle mill prototype showed some technical errors, so they rebuild and adjusted the machine until it was correct. During the first production process the yarns knotted together. The only solution was to proceed the process partly by hand. Tjeerd has studied the spooling process from India, where the people work this process by hand. Carolijn continued this work plan for all the remaining KM dyed yarns. I am very thankful and happy with such amazing collaborators. My compliments for their love and dedication.

-

Update 1: 24-04-2020

It´s required to add base materials to create the fabrics. I realize that we can not only use Archi-Filament to develop the Marinero fabrics. It is very important that we have a solid yarn that can be applied as a base material. Most of the collection will be produced with double weaving techniques. This means that you have 2 layers of fabrics crossing and connecting with each other. One of these 2 layers will be applied with Seacell yarn. This yarn is produced in Switzerland. It’s a mix of Seacell and silk twisted into one yarn. The Seacell yarn is produced in its original pure ivory color. This yarn could be very well dyed with natural pigments. I contacted De Wasserij in Rotterdam to ask if they could connect me to local Dutch seaweed dyeing companies. My idea is to add more depth to the Seacell yarn, by dyeing the yarn with seaweed pigment. It could be very interesting to add gradient techniques into the fabric design. Esther Muñoz Grootveld advised me to contact Studio Carolijn Slottje and Tjeerd Veenhoven. After our first meeting we agreed to first test the quality of the seaweed. Some Seacell yarn samples were shipped to the studio of Carolijn in Groningen. Carolijn made some dyeing with seaweed pigment experiments. The quality of the first test was approved. Team Slottje accepted the challenge to dye larger quantities of Seacell silk yarns.

Carolijn has great experience working with natural materials. We decided to approach the collaboration like an experiment. It´s the first time that Team Slottje is working with dyeing large quantities of yarns. We needed to be inventive in finding solutions step by step. Some wooden spooling machines were even created by hand. This idea helps the production process to work more smoothly. It seemed to be much more work than initially planned. Luckily the team got motivated to put more time into the process. I am very thankful that team Slottje has put so much effort and love into this collaboration. The points below show the steps made to dye the yarns:

- Rinse the yarn

- Tie the yarn into bundles

- Pickling yarn

- Cooking the seaweed

- Sieving the weed

- Creating color baths

- Adding the yarn into the bath

- Drain the yarns

- Wind yarns on the cones

At the end of the project you will see the final result of the Seacell yarn golden mint green color. The seaweed pigments are not consistent throughout the whole yarn. Meaning that some parts of the yarn are more intense green. I personally really like this hand made approach and feel. This collaboration was a learning process for all partners involved. Looking forward working together again with this amazing team in the future.