Update 5: 29-07-2020

*Weaving Mix 1 category

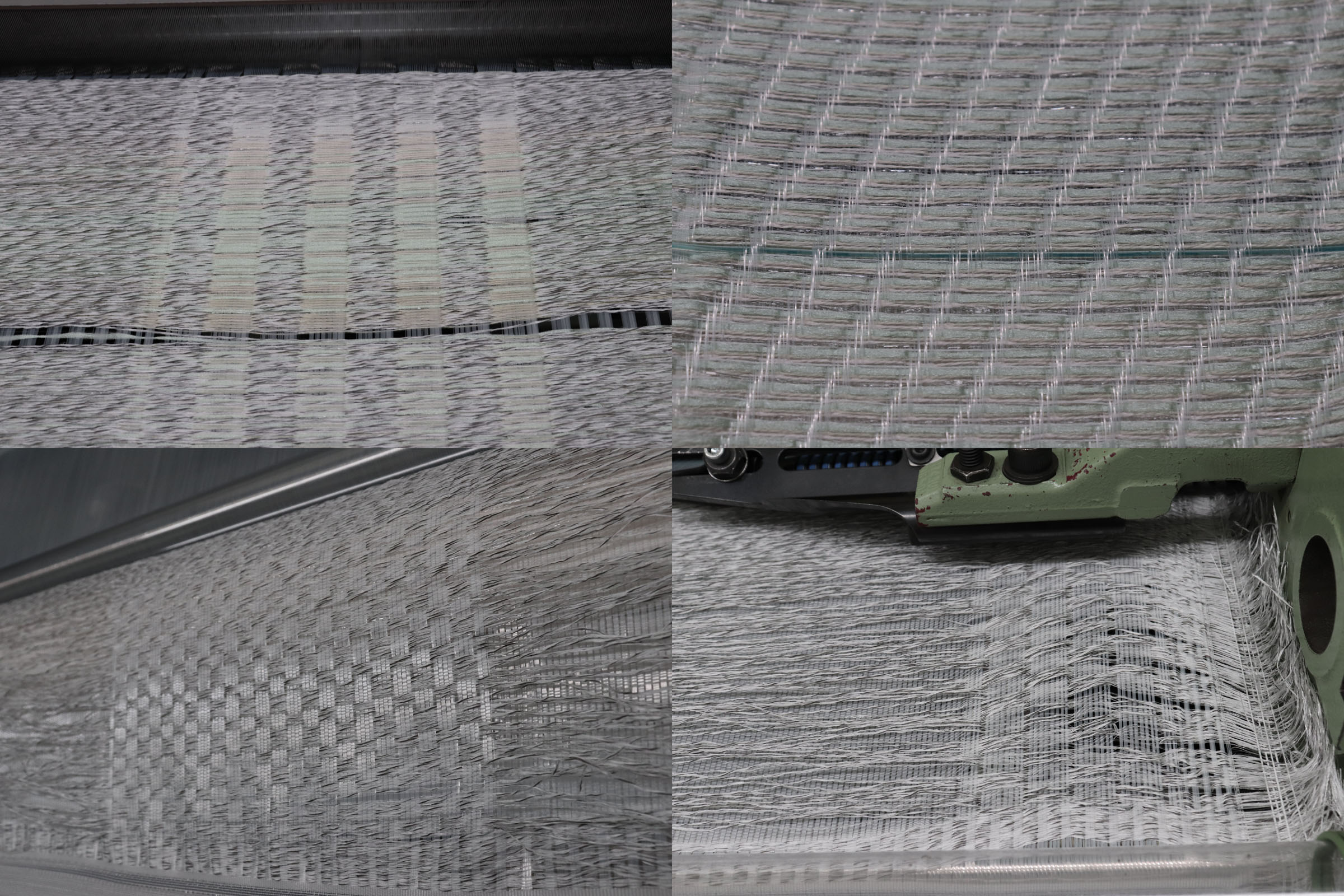

The last step made for the weaving category was a very surprising one. For the mix 1 category I initially wanted to mix the Re-FREAM developed yarns and add several yarns from TextileLab. But during the first fabric sample I realized that I wanted too much of the good stuff. I informed my product developer to cancel all initial plans for the mix 1 category and start over again. I focused on just wanting to combine the WK+ with Aitex yarns and make a beautiful marriage between those two.

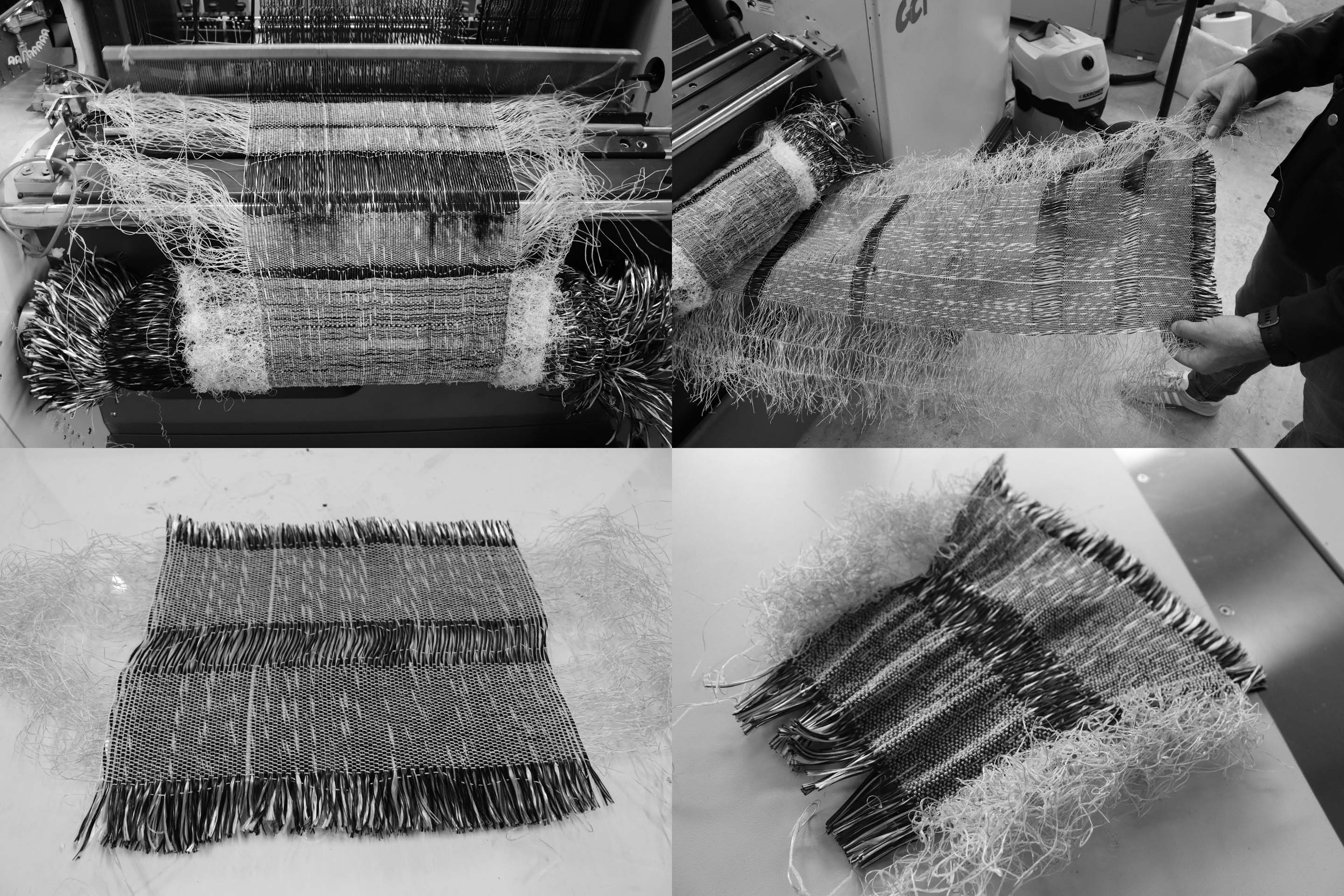

I was lucky that we had room left to cancel one initial idea and to reproduce an entire new idea. Judith and me had a discussion on what would be the best way to rethink this process. We decided to go an entire new direction using as less yarns possible. To focus on a few elements and create the fabrics based on the yarn characteristics. We wanted to go more fragile while using stiff yarns. So, we had to focus on making the fabric structure more open and loose.The most important focus was to design the fabric in a very fragile way. This would allow the adaptive yarns to move around through the structures more easily. We needed to frame the fabric blueprints all the way through. Meaning that these frameworks would hold the whole structure together and not able to burst around the edges. The first mix 1 fabric test that we did was way to firm and bulky. So, we downsized the yarn options by just combining the Aitex with the WK+. It turned out that yarn limitation allowed us to research a wider spectrum of complex binding techniques.

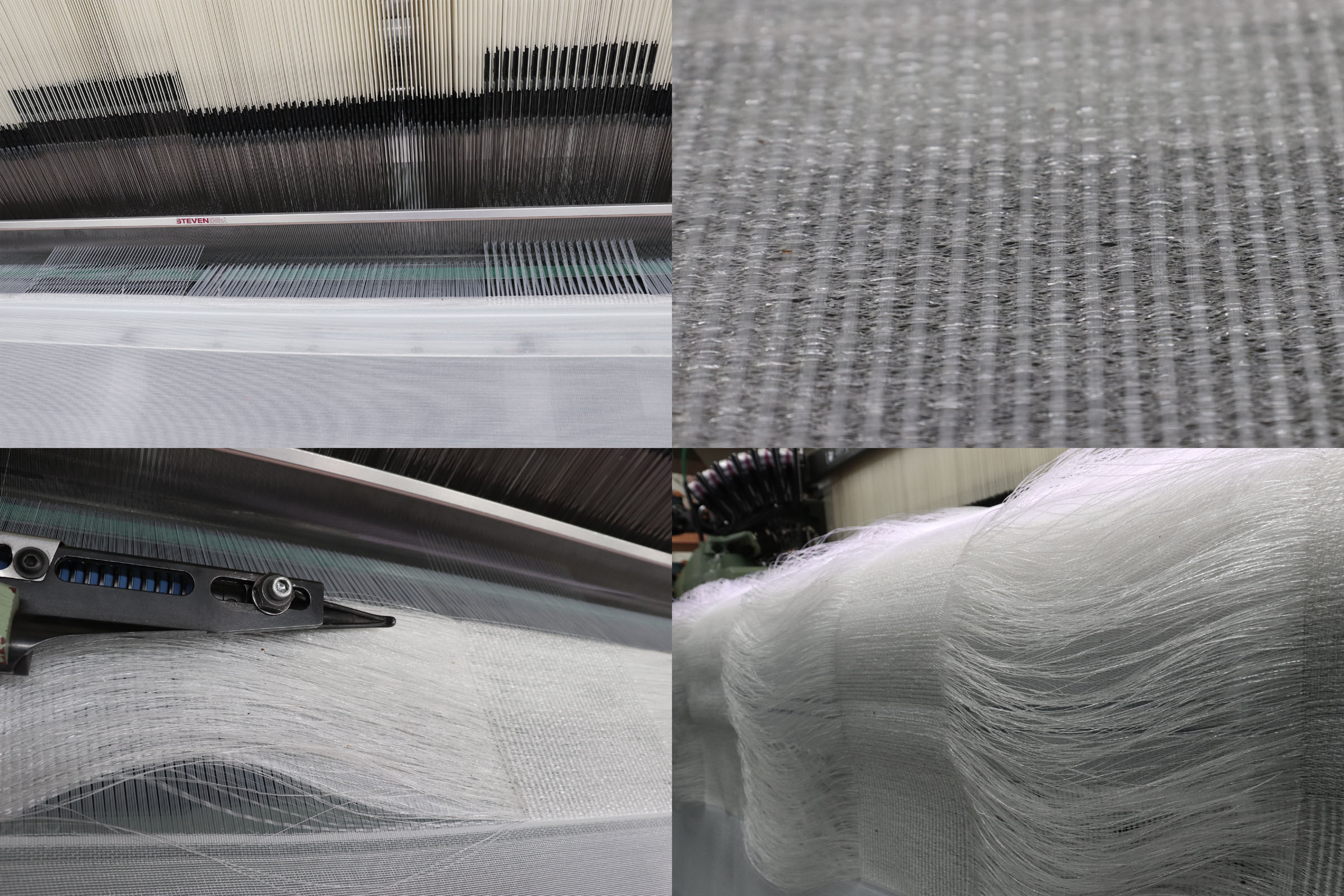

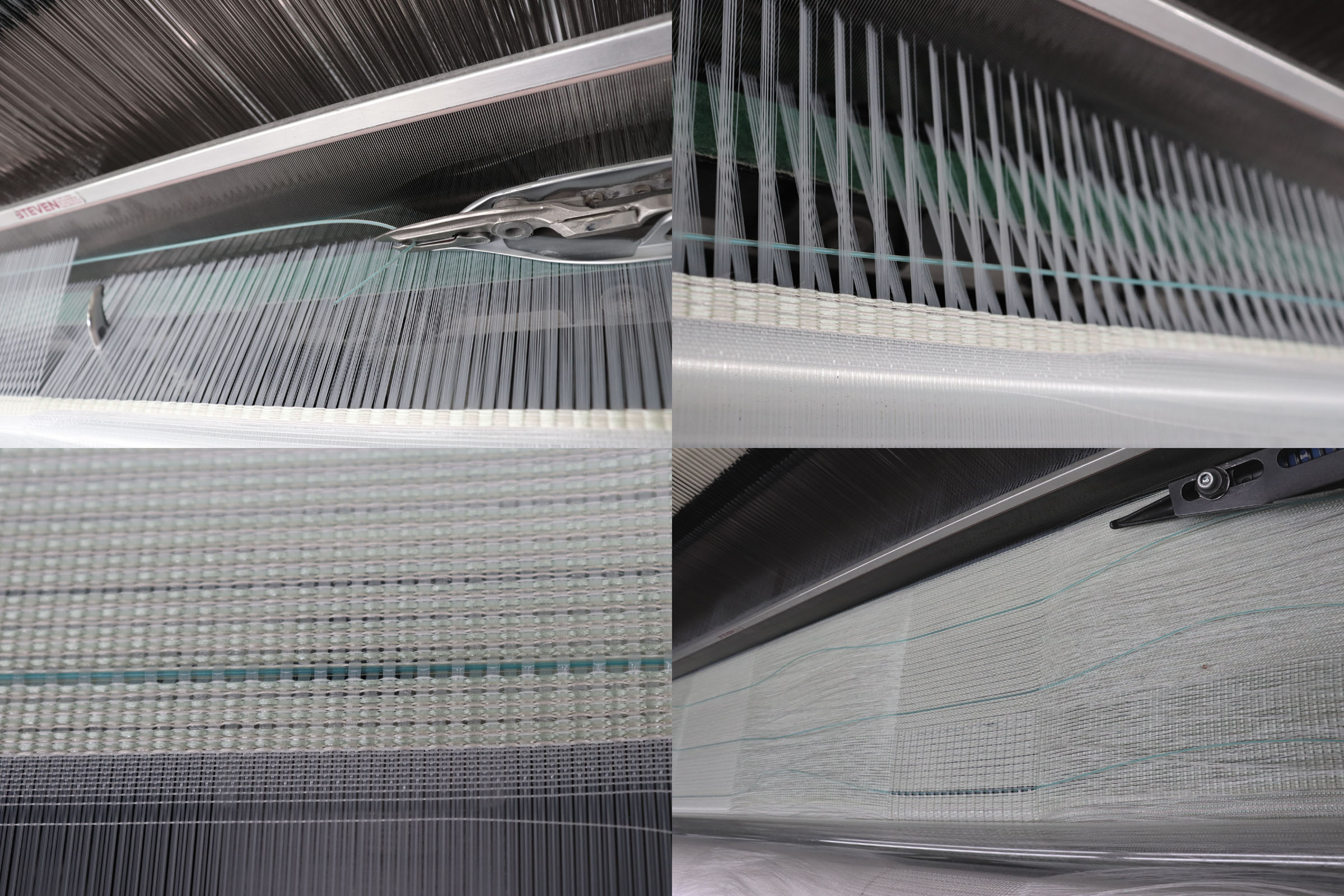

TextileLab weaving production steps made to create the Marinero fabrics:

- Adding the monofilament warp onto the weaving machine

- Product developer & designer blueprint evaluation

- Product developer preparing the digital blueprint programs

- Technicians installing all the correct yarns for each fabric

- Technicians correcting and re-spooling pre-produced dyed yarns

- Product developer preparing all the production documents

- Technicians twisting new yarns to complete the production

- Designer putting the fabric prototypes on the mannequin

- Product developer & designer evaluating fabric on mannequin

- Product developer last adjustments, based on mannequin evaluation

- Weavers producing the fabrics, based on production documents

- Weavers manually adding thick filaments by hand if needed

-

Update 4: 29-07-2020

*Weaving WK+ category

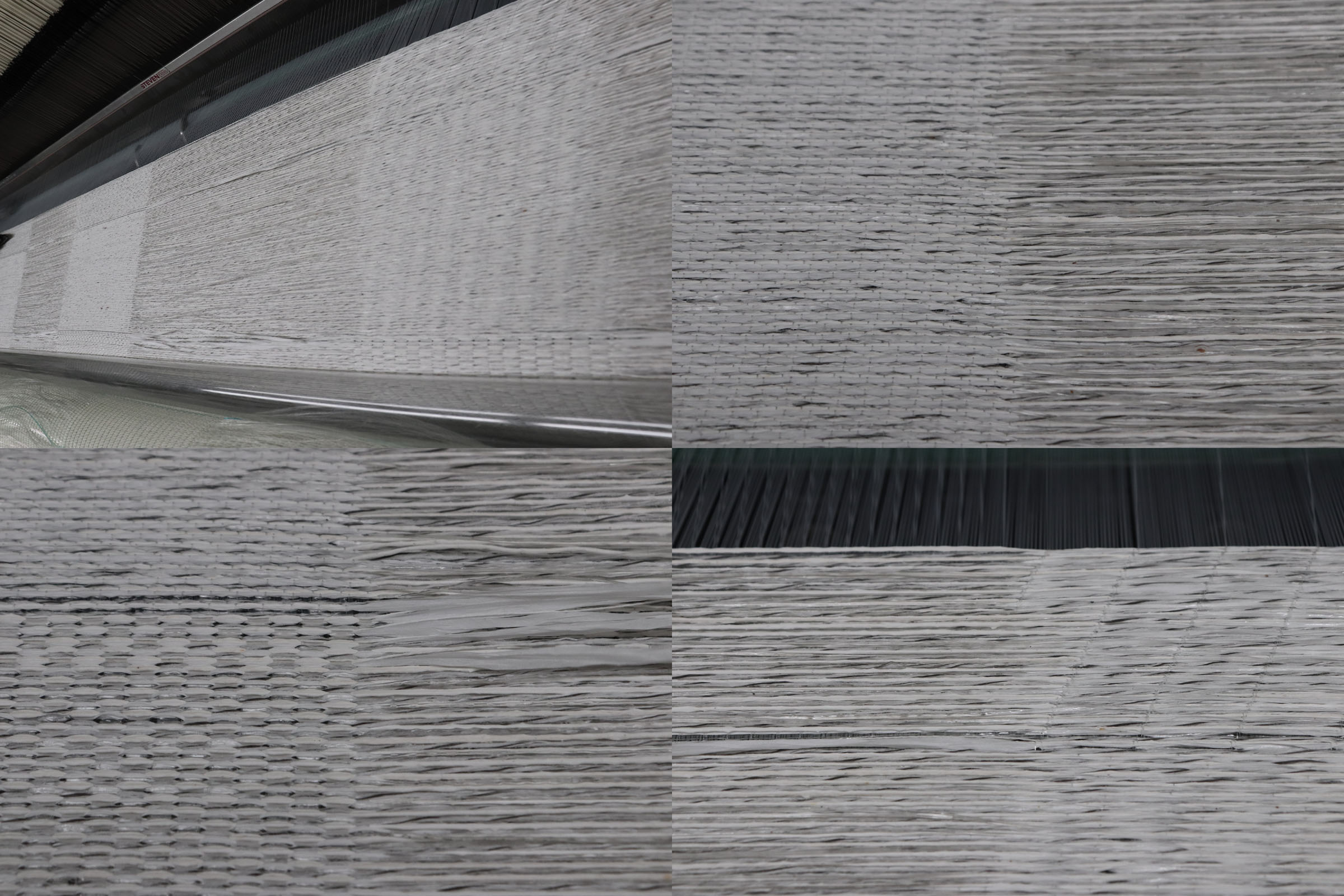

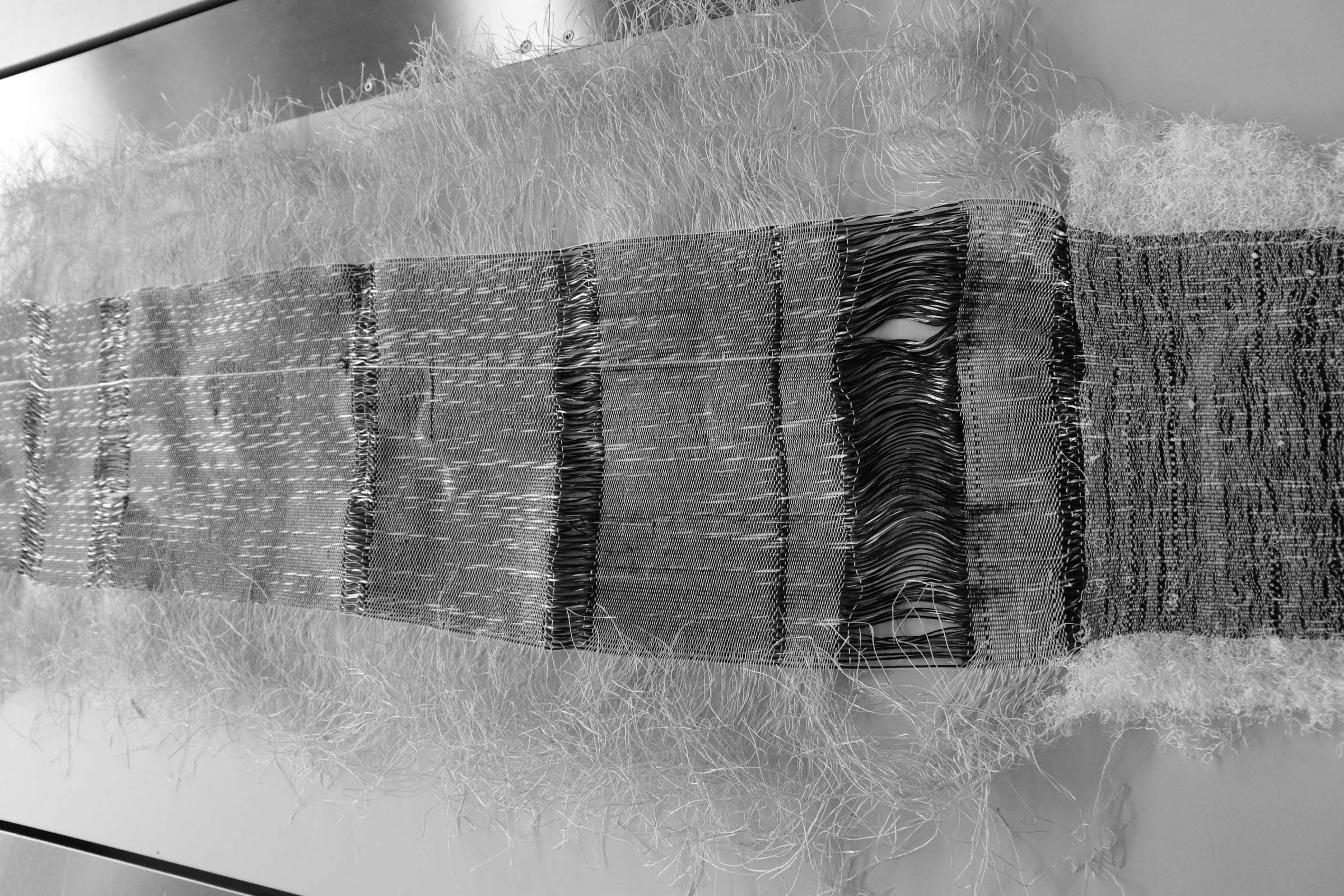

The second fabric category that we worked on was about combining monofilaments. With Wood K Plus we had the test 1 and test 2 filament option. The idea was to create double weaving techniques using the WK+ filaments. It was very surprising to see the textured monofilament within a fabric sample. The effect of test version 1 shimmers like a wet spiderweb. However, test version number 2 was not able to be woven. The maximum thickness that is allowed is 0,4 mm and test 2 is 1,1 mm thick. There was only one solution left: to add all the test version 2 filaments by hand. This was a real time consuming challenge. So, we had to make a strict schedule, with the time left that we had planned for the production.

The technicians were so kind to offer to try and work with the inlay technique. Meaning that they need to cut test 2 by hand and add it into the textile. They need to repeat this process until the fabric is finished. I am very thankful that they wanted to help me with this process. They worked several weekend shifts, in order to finish the whole fabric production. For the entire project we had 6 fabric designs planned using the test 2 filaments. We decided to shift the cm’s for each design:

- Design 1 ( WK+ category ) = repeat process after 7 cm

- Design 2 ( WK+ category ) = repeat process after 14 cm

- Design 3 ( WK+ category ) = repeat process after 21 cm

- Design 4 ( Mix 1 category ) = repeat process after 7 cm

- Design 5 ( Mix 1 category ) = repeat process after 14 cm

- Design 6 ( Mix 1 category ) = repeat process after 21 cm

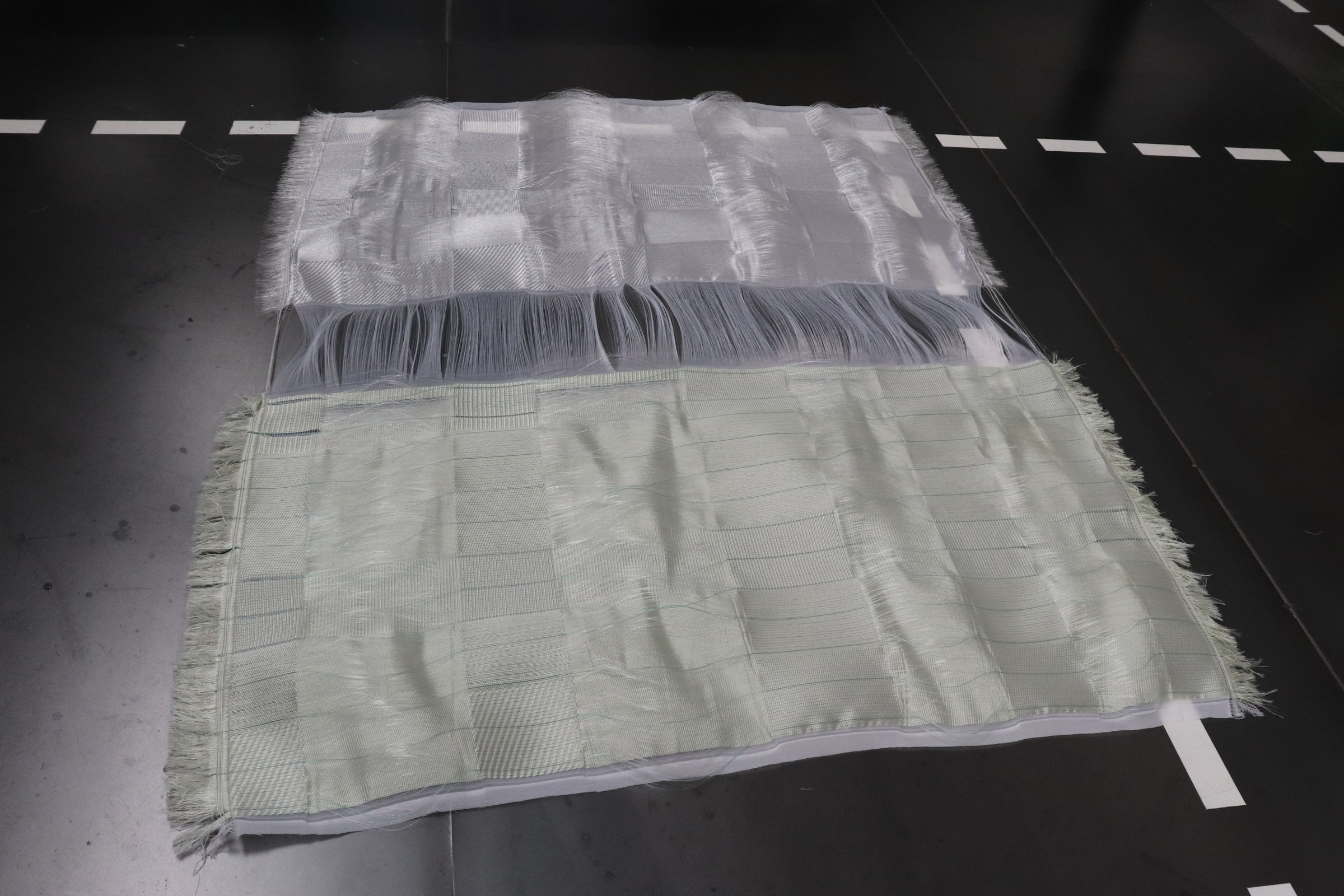

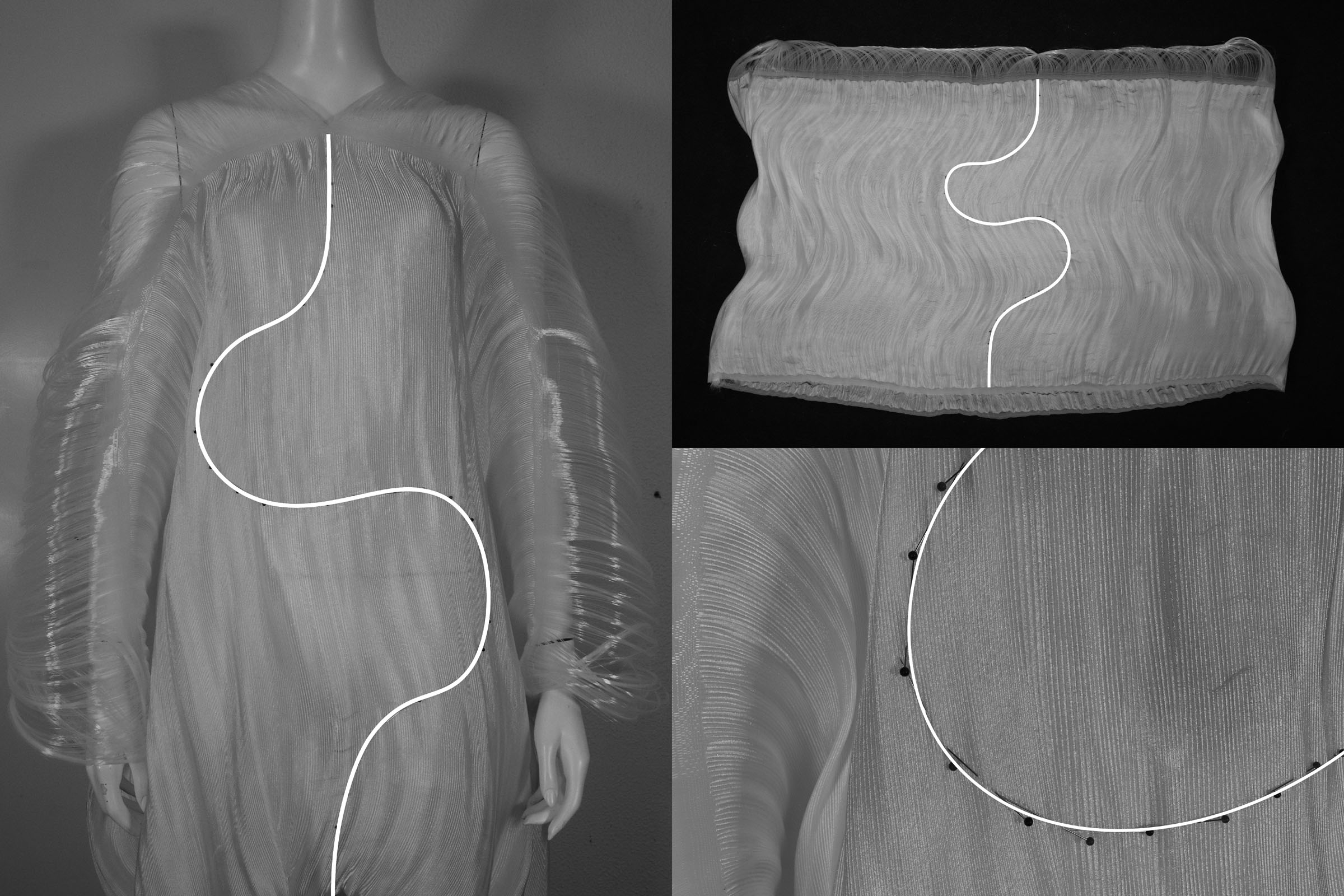

The Test version 2 fabric shows large volume contrasting shapes. After this fabric sample was produced, I draped it onto a TextileLab mannequin. It was very inspiring for me to see the WK+ test 2 fabric shape. This will be very interesting in terms of the tailored by weather effect. The filament becomes more and more flexible during the rain, creating a crystallized melt coating texture. Meaning that the WK+ garment samples will go from monumental round towards wavy volumes.

-

Update 3: 06-06-2020

Last month I prepared some initial blueprints for TextileLab. It will be very important to be clear about each developed prototype. I prepared a detailed list and emailed it to the product developers of TextileLab. I will be working together with Judith Peskens for the weaving production. For the knitting production I will collaborate with Sarena Huizinga and Damien Semerdjian.

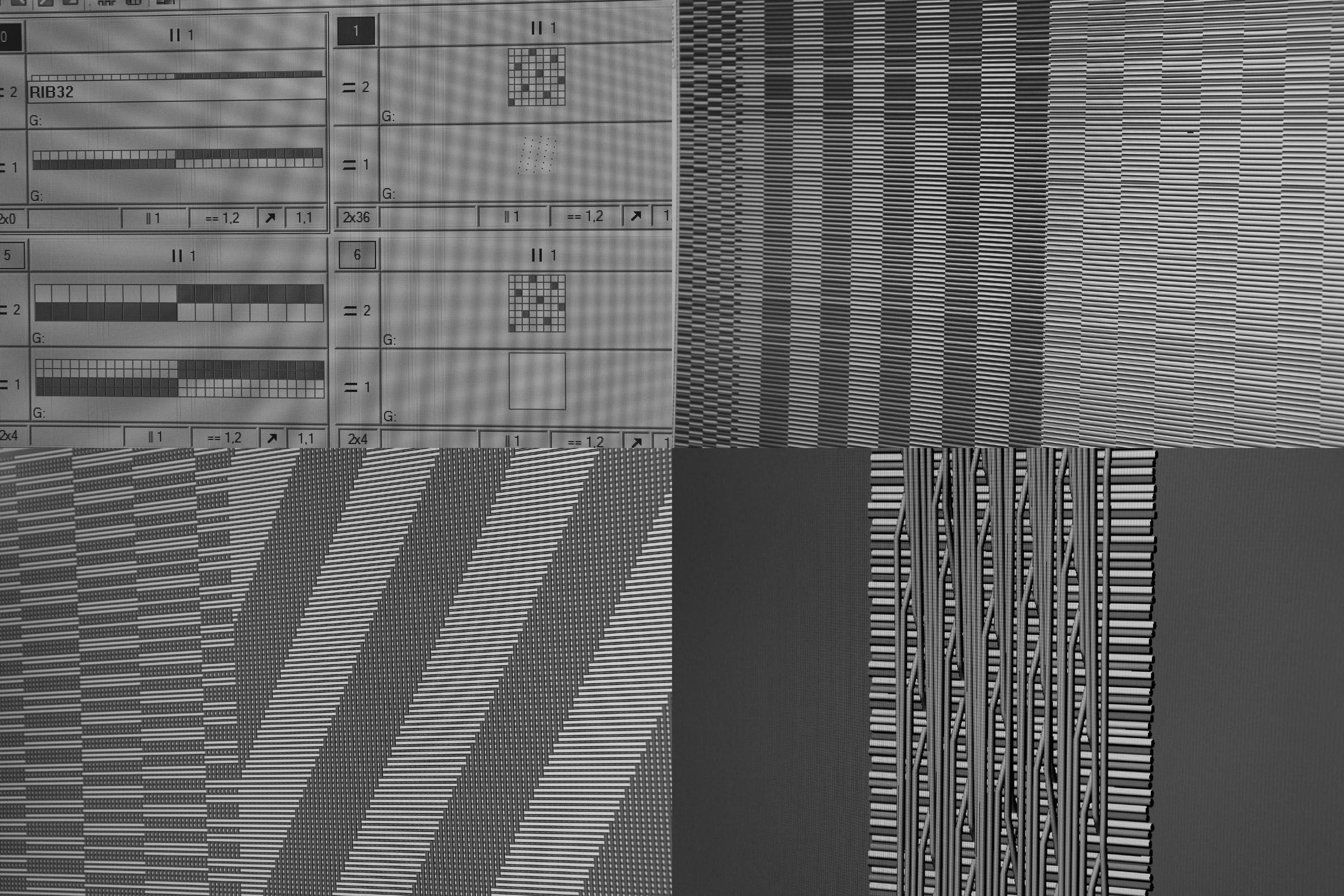

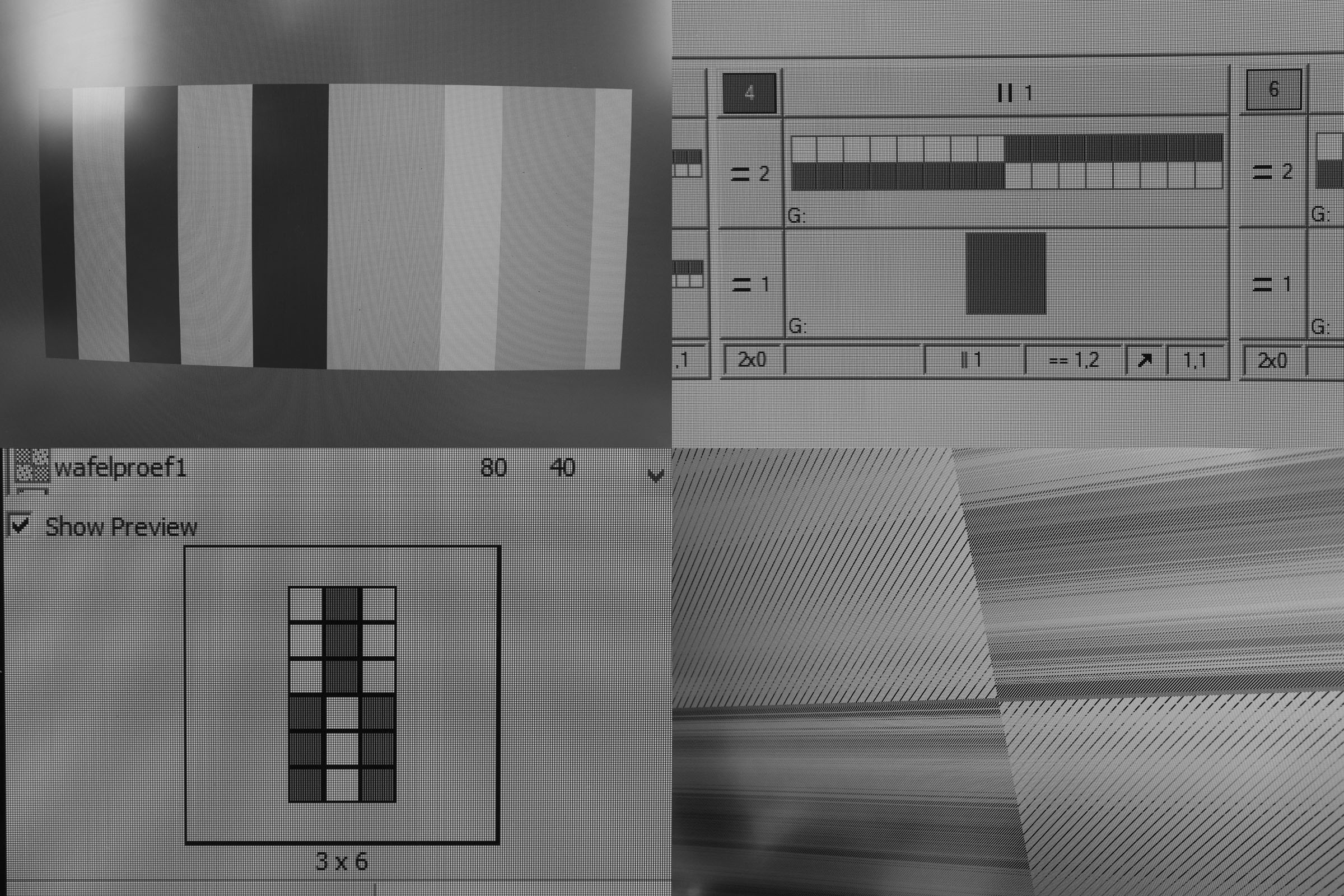

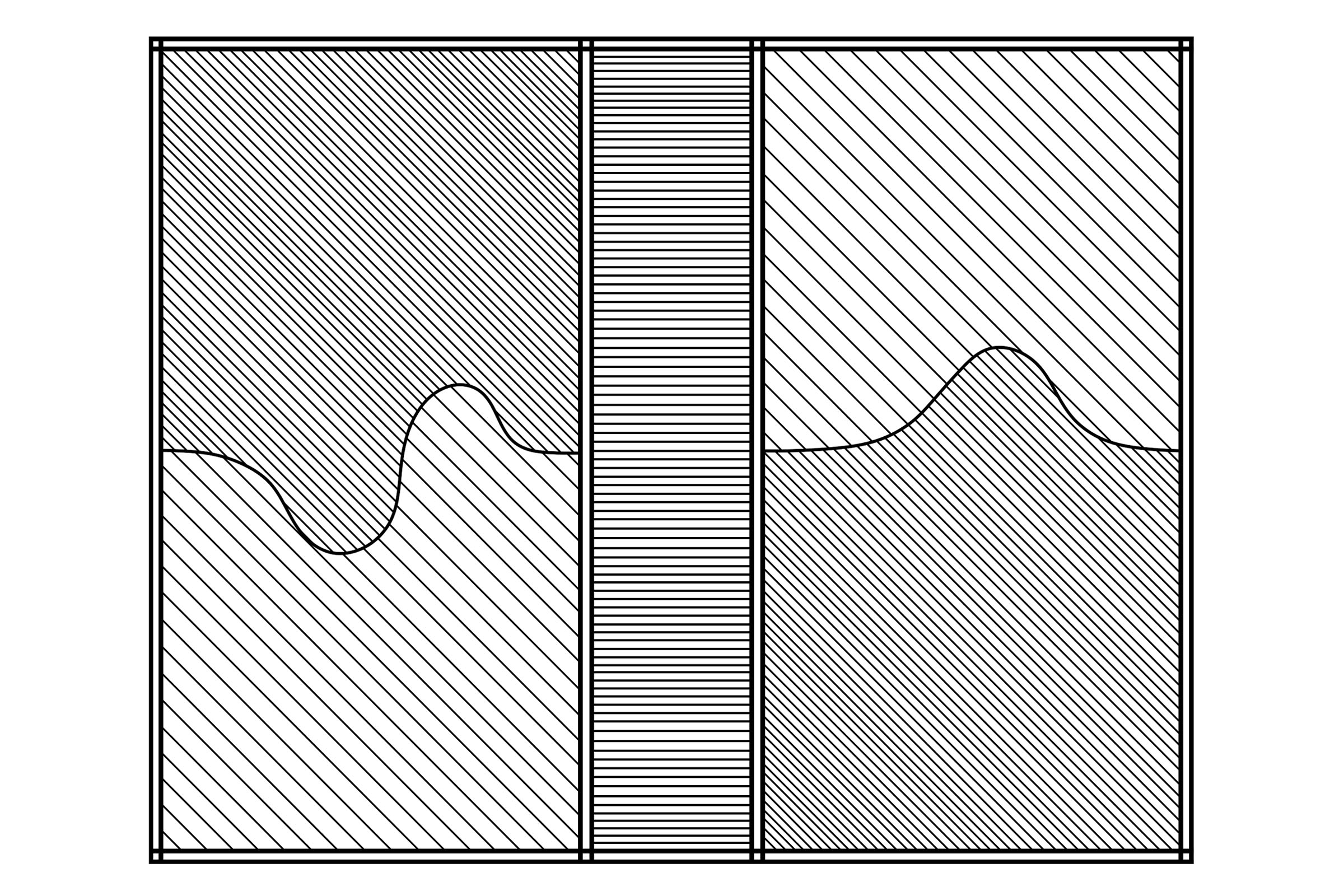

For the textile production I will be working with the developed Re-FREAM yarns. It was important to finish all yarn productions before I start working at TextileLab. Next to my own developed yarns I will also use some of the yarns and filaments that TextileLab has available. All these yarns will be programmed and prepared for the digital textile blueprints. The wave pattern that I created last month seemed not to work. I realized that I want to create a wavy shape, by the use of the Adaptive Archi-Filament. Meaning that this can only be done by starting with straight lines (and not to start with a wavy pattern line). These straight pattern lines will eventually become a deformed wave shape.

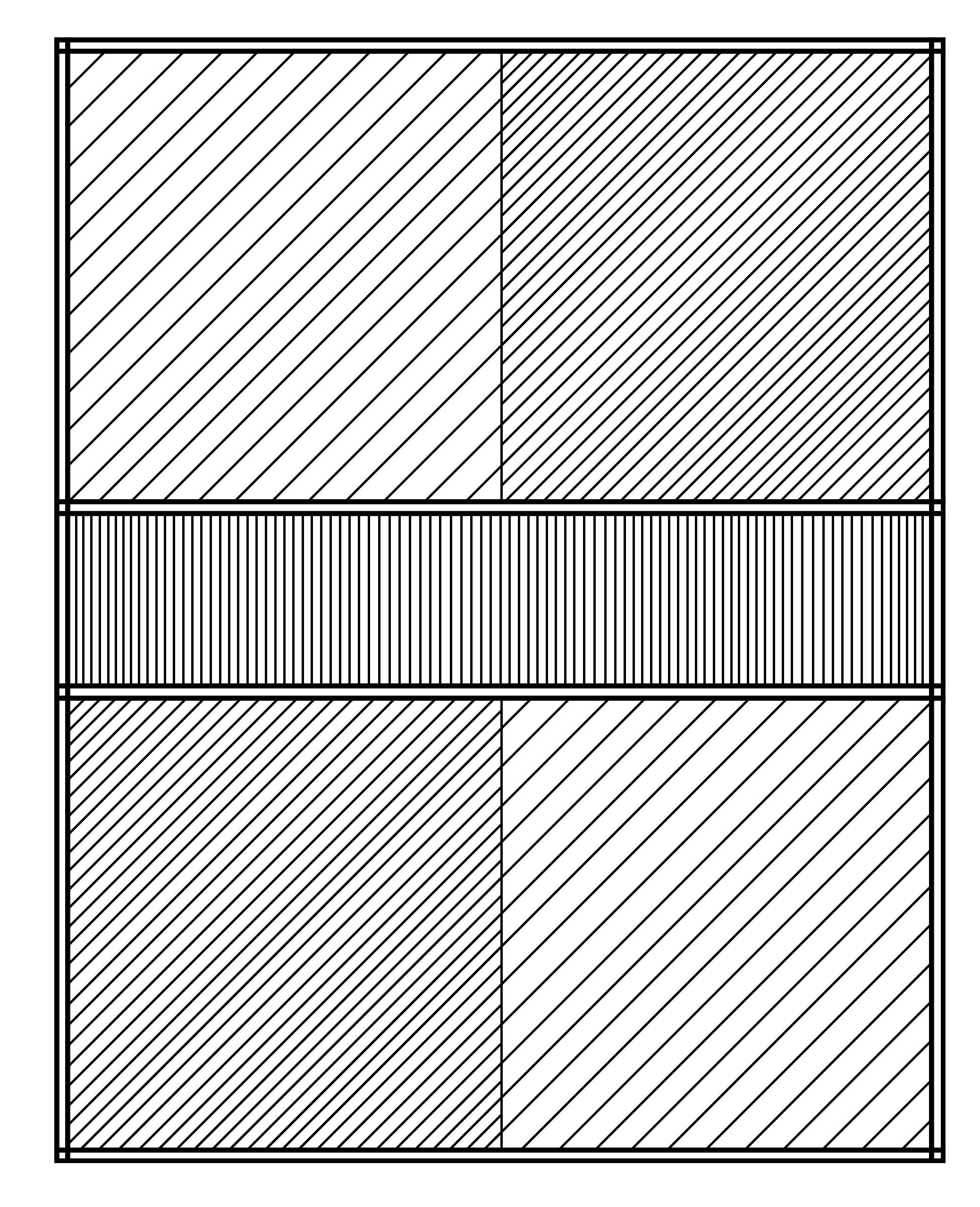

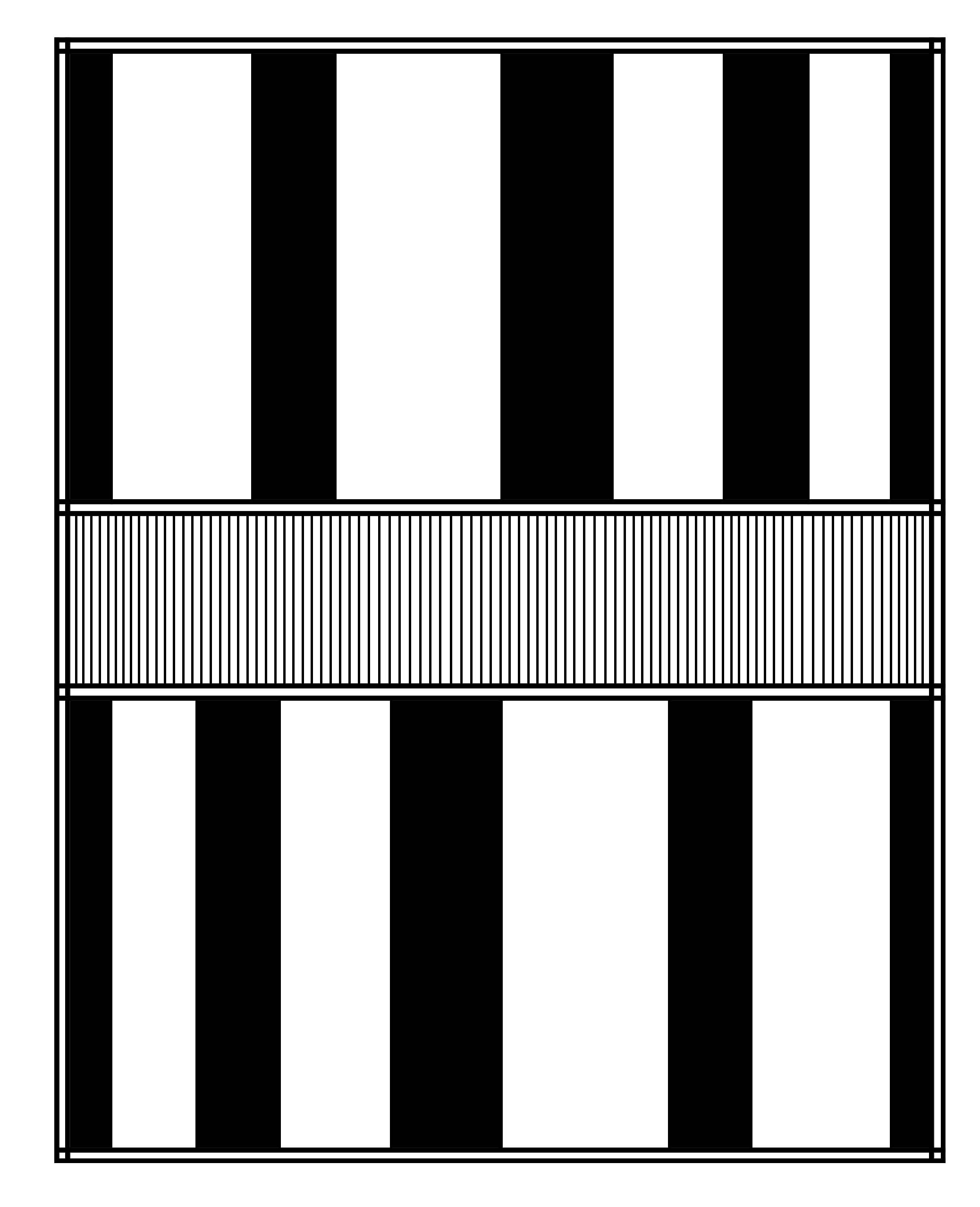

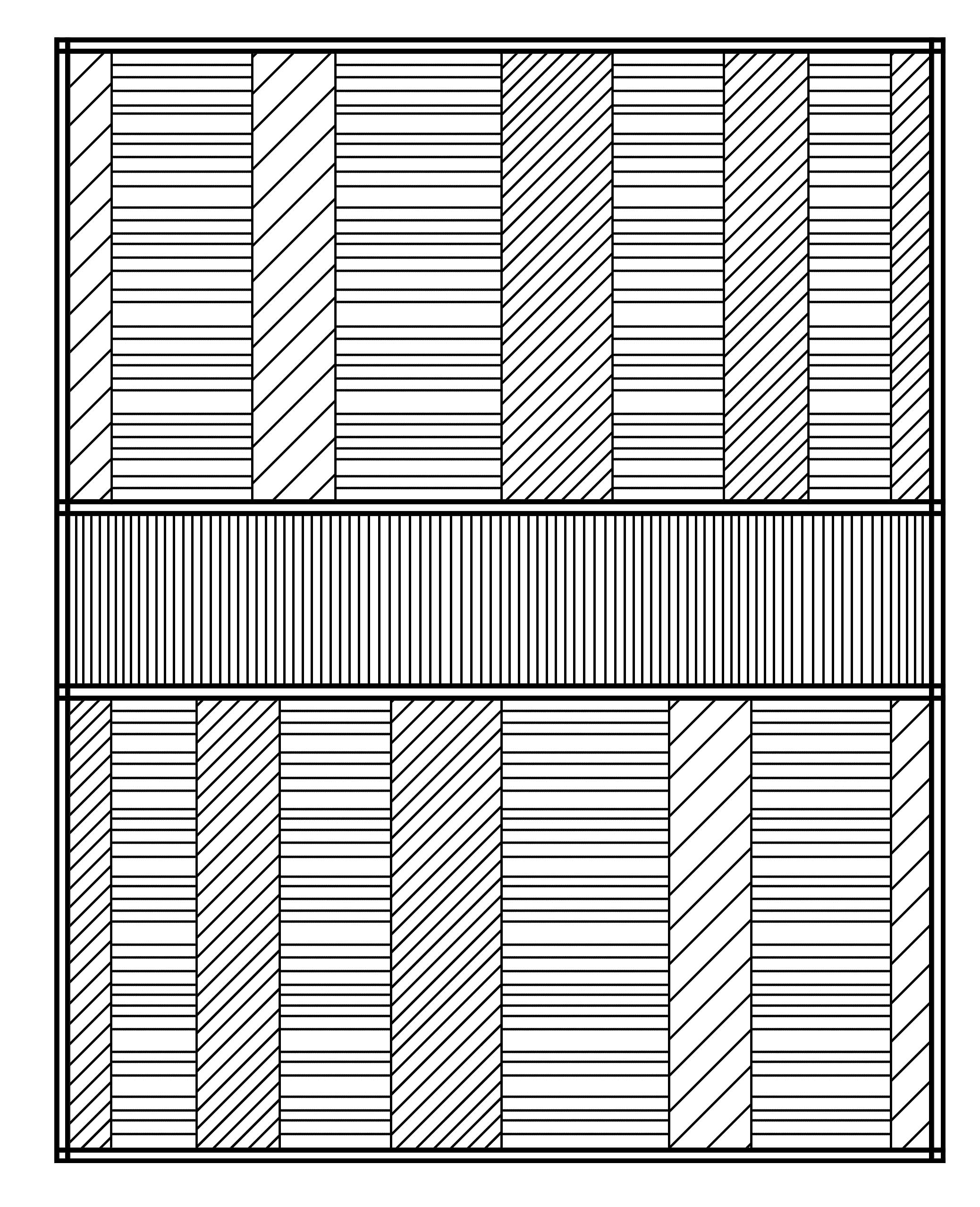

The technical blueprints below showcase examples on how some pattern layers are prepared. These three example layers will eventually become one Marinero garment. Luckily I had some extra time to prepare these adjustments. Good preparation is everything! In June and July I will be working at TextileLab Tilburg.

-

Update 2: 30-04-2020

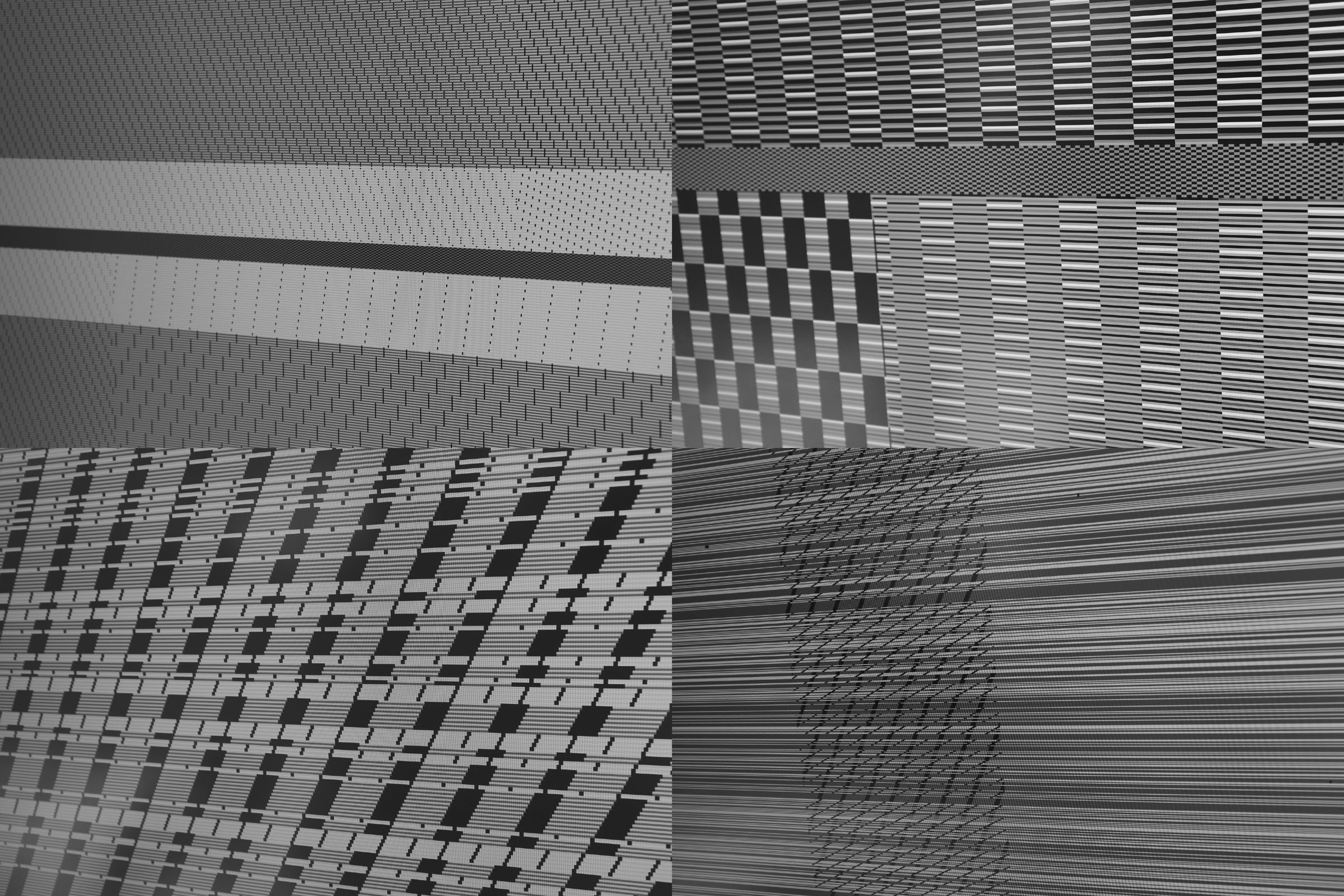

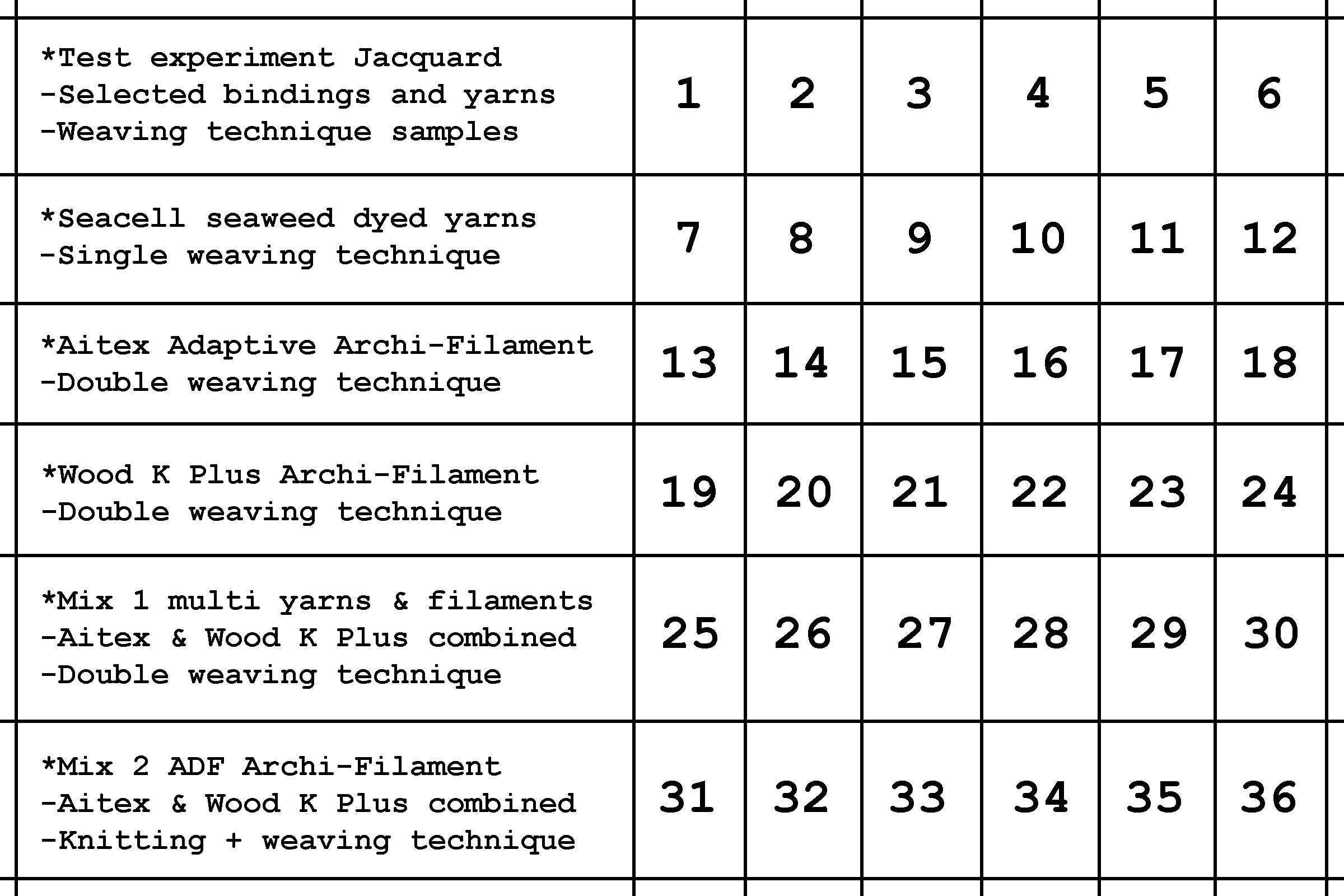

The postponed TextileLab Tilburg meetings allowed me to prepare everything in a more detailed way. I choose to use the best of the extra time to prepare my plans. I will be working on technical drawings that I will share with the TextileLab product developer. This will help the product developer to understand better about what I have in my mind. We will collaborate as a team, so it’s best to be as crystal clear as possible! There are 30 woven designs planned + 6 extra knitting samples ( 6 x 6 ). It will be better to prepare all the 30 weaving designs in terms of technical blueprint drafts. There are 5 weaving categories that will be divided in single and double weaving techniques. Each category has its own style and specific types of added weft yarns. Underneath you will find a global overview of initial plans that I have for the 5 x 6 Jacquard weaving and 1 x 6 ADF knitting designs.

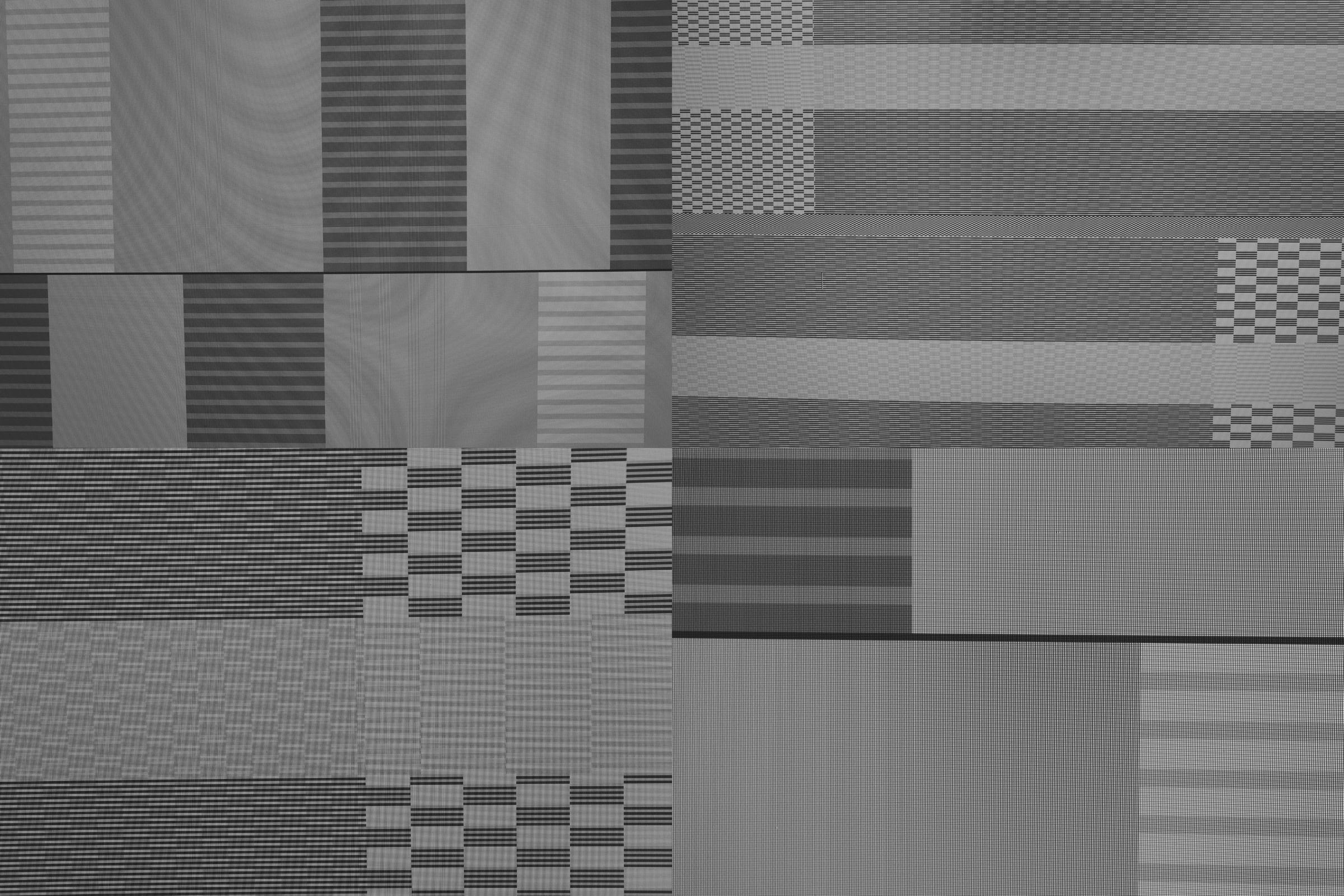

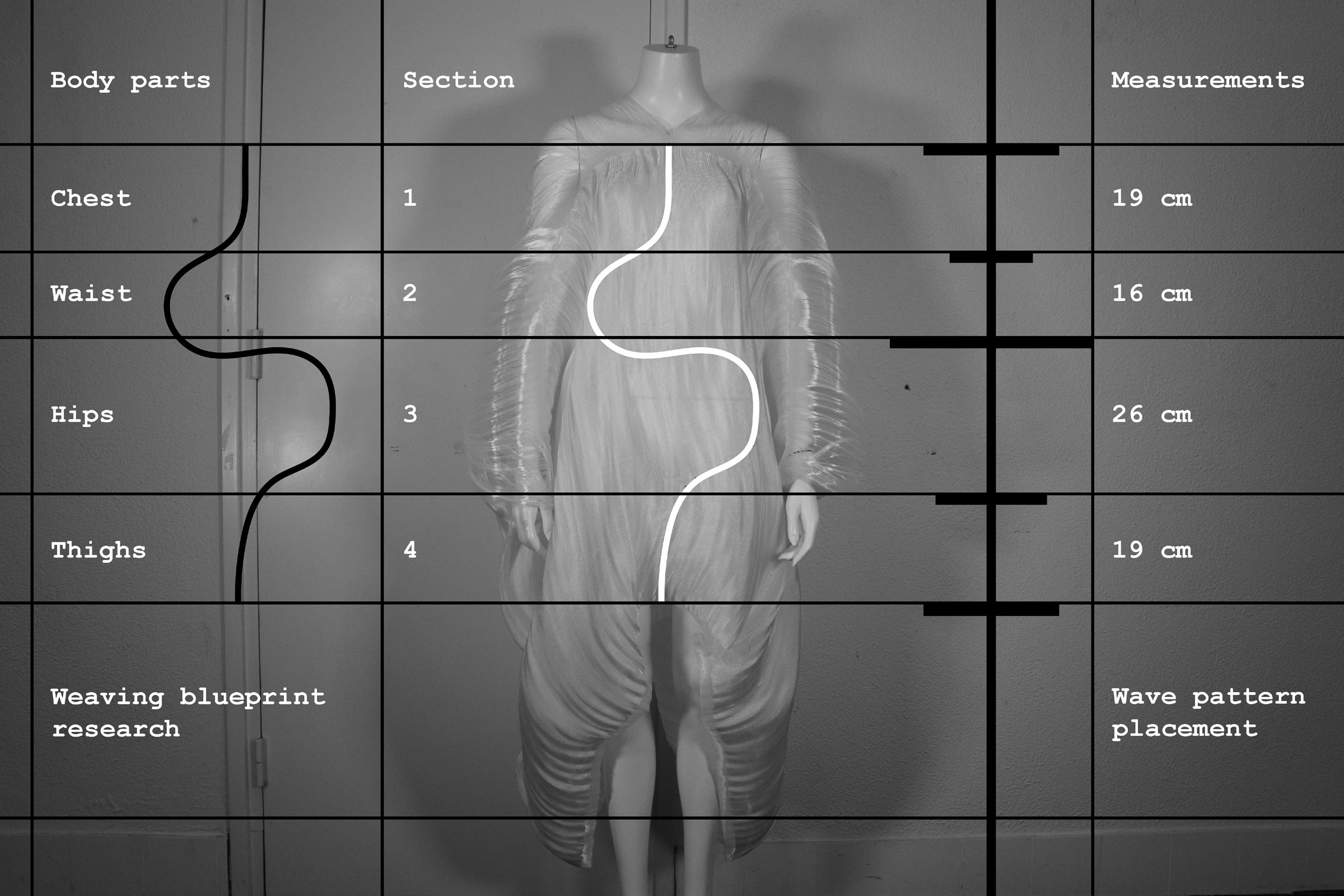

In my studio I started working with the first Marinero prototype. I used pins to find the correct balance between the chest, waist and hip area. Following this path creating a wave pattern. This pattern is used to divide different bindings within the weaving blueprint. In the photograph above you can see a sample how each body section is divided. This will help the design to shift asymmetrical during the transformation process. Section 2 for example will have the tailored waist effect. The waist technique will be emphasized by adding more Adaptive Archi-Filaments within this frame. At the drawings below you can see an example of a technical weaving blueprint. It’s a very open twill versus a tight woven twill technique. This will help to shift the design asymmetrical during the transformation process. Each fabric design category has 6 final prototypes. The enclosed matrix shows an example of each category and its selective added yarns. During the coming months I will give you more insight on how we work step by step towards the tailored by weather experiments.

-

Update 1: 07-12-2019

In november the first prototype of the Adaptive Archi-Filament came to life. In the facility of Aitex it is possible to do small 50 cm width weaving samples. This is very interesting to test the designed filaments! We can prototype several yarns and filaments and test the weaving possibilities. The idea is to have a handful of approved initial signature archi-filaments, and send them to the TextileLab in Tilburg. If the team of TextileLab approves of the yarns Aitex in Alcoy can start the production of the Adaptive Archi-filament. Underneath you can see some initial weaving test using the first prototype of the Adaptive Archi-Filament within a weaving. The filament by itself has a very dramatic reaction to water. For the first weaving test we used carbon in the vertical (officially this will be 0,2mm white mono-filament) The Adaptive Archi-Filament shows a minor adaptive change when applied with water in combination with carbon. With mono-filament this will work a lot better. More updates follow up soon!

-

TextileLab - TextileMuseum Tilburg is the official partner of creating the jacquard weaving for project Marinero. Together with the product developers and yarns adviser we will team up to realize the digital blueprints. The first step will be to test our own developed yarns. The TextileLab team are an important partner to advise me about what is possible to work with or not. Kevin and Jef will work on creating the wave technical pattern drawings. These patterns will be send to the TextileLab product developer. The weaving production can be scheduled when all the yarns are produced and final tests are approved. The whole collection will be woven on the jacquard machine. After that the fabric role will be transported to the Studio of Adaptive Skins. Arrived in Arnhem the blueprints will be cut, stitched and installed for at least one month in open air. On this page the whole process of creating the jacquard weaving will be updated regularly.

Photo @ TextielMuseum Tilburg